What is Cold Chamber Die Casting

In the world of manufacturing, you might find different methods to shape metal into parts. One effective way is cold chamber die casting, which is suitable for metals with a high melting point. This technique uses high pressure to inject molten metal into a mold.

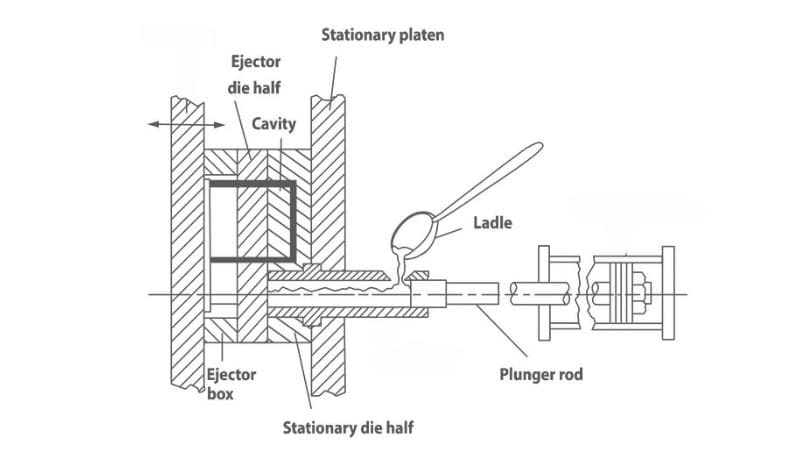

The Components of Cold Chamber Machine

The cold chamber die casting machine comprises several essential components that work together to produce precise metal parts efficiently.

The injection system, typically a hydraulic or mechanical piston, is responsible for injecting molten metal into the die.

The shot chamber ensures controlled injection by minimizing the metal’s contact with the system. The die assembly, consisting of male and female halves, shapes the molten metal into the desired form. A robust clamping mechanism holds the die halves together under high pressure during injection.

Once the metal solidifies, the ejection system uses ejector pins or plates to remove the finished casting without damage.

Integrated cooling channels within the die regulate temperature, ensuring proper solidification and reducing cycle times.

Additionally, the hydraulic system powers both the injection and clamping mechanisms, providing the necessary force for smooth and effective operation.

The Manufacturing Process of Cold Chamber Die Casting

The cold chamber die casting process begins with the selection of appropriate metal alloys; these metals are first melted in an external furnace, ensuring they reach the necessary liquid state without contamination.

Once liquefied, the molten metal is carefully transferred into the shot sleeve of the cold chamber die casting machine, a process that requires maintaining the metal at a consistent temperature to prevent premature solidification.

The cold chamber setup allows for greater control over higher melting point metals, enhancing the versatility of the process.

Next, the die, which has been meticulously prepared and clamped shut to withstand high pressures, plays a crucial role in shaping the metal. The die consists of two precisely machined halves that form the mold cavity, matching the desired geometry of the final product. A hydraulically operated plunger or piston then exerts immense pressure to force the molten metal from the shot sleeve into the die cavity. This high-pressure injection ensures that the metal permeates every intricate detail of the mold, eliminating air pockets and ensuring structural integrity.

Once the die cavity is fully occupied, the metal begins to cool and solidify rapidly within the confines of the die. The cooling time is meticulously controlled to achieve the optimal hardness and strength of the casting. After sufficient cooling, the die halves are separated, and ejector pins activate to precisely remove the solidified casting without causing any surface defects or distortions.

What are the Clamping Force and Cycle Time?

Clamping Force

Clamping force is the force applied by the die casting machine to hold the two halves of the mold tightly together during the injection of molten metal.

The clamping force can be calculated using the formula:

Clamping Force=Cavity Pressure×Projected AreaClamping Force=Cavity Pressure×Projected Area

Where:

- Cavity Pressure is the pressure exerted on the molten metal during injection.

- Projected Area is the area of the mold that is perpendicular to the direction of injection.

For example, if a part has a projected area of 120 cm² and requires an injection pressure of 800 kg/cm², the clamping force needed would be calculated as follows:

Clamping Force=800 kg cm2×120 cm2=96,000 kg or approximately 96 tons

Cycle Time

Cycle time in cold chamber die casting refers to the total time taken from one injection cycle to the next. This cycle typically includes several phases: clamping, injection, cooling, and ejection. The total cycle time can vary widely but generally falls between 2 seconds and 1 minute.

Components of Cycle Time

- Clamping Time: The time taken to close and secure the mold halves before injection.

- Injection Time: The brief period (usually less than 0.1 seconds) during which molten metal is injected into the mold.

- Cooling Time: The duration required for the molten metal to solidify fully within the mold. This can vary based on wall thickness and material properties.

- Ejection Time: The time taken to open the mold and eject the finished part.

What are the Advantages of Cold Chamber Die Casting?

It can handle metals with high melting points, like aluminum and copper alloys, by using an external furnace, which ensures better temperature control and prevents premature solidification. This method enables the creation of intricate and precise shapes with excellent surface finishes, as the high-pressure injection fills every detail of the mold without air pockets.

Additionally, the dies used in cold chamber die casting are more durable since they experience less thermal stress, resulting in longer service life and reduced maintenance costs. Quality control is enhanced through precise monitoring of temperature, pressure, and injection speed, leading to consistent and defect-free castings. The process also offers greater flexibility, allowing for the production of larger and heavier parts suitable for industries like automotive and aerospace.

Furthermore, operational efficiency is improved because the external furnace simplifies maintenance and reduces downtime.

Comparison with Hot Chamber Die Casting

Hot chamber die casting is different mainly because the chamber is in constant contact with the molten metal. The process is more suited for metals with lower melting points. In hot chamber die casting, a chamber connected to the die cavity is submerged in the molten metal. A piston directly forces the melted metal into the die without the need for ladling.

Here’s what sets them apart:

| Aspect | Hot Chamber Die Casting | Cold Chamber Die Casting |

| Furnace Location | Built into the machine, directly connected to the die | Separate from the machine, molten metal ladled into the shot sleeve |

| Cycle Time | Shorter, faster production cycles (~15 casts per minute) | Longer cycle times due to manual metal transfer |

| Metal Compatibility | Suitable for low-melting-point alloys (e.g., Zinc, Magnesium) | Suitable for high-melting-point alloys (e.g., Aluminum, Copper) |

| Injection Pressure | Lower pressure (1,000 – 5,000 psi) | Higher pressure (2,000 – 20,000 psi) |

| Tool/Dies Life | Longer die life due to lower metal temperatures | Shorter die life due to higher metal temperatures |

| Production Volume | More efficient for high-volume production | Better suited for lower-volume or larger parts |

| Part Complexity | Suitable for small, simple parts | Ideal for larger and more complex parts |

| Surface Finish | Excellent surface finish and dimensional accuracy | Good surface finish but may require post-processing |

| Safety Considerations | Fewer safety concerns due to lower temperatures | Requires more safety measures due to handling of higher temperature metals |

| Initial Setup Cost | Lower due to simpler setup | Higher due to additional equipment (separate furnace) |

Right Material for Cold Chamber Die Casting

In cold chamber die casting, choosing the right material is vital as it directly influences the mechanical strength and heat handling of your parts.

When selecting the material for your cold chamber die casting project, you have various metals to choose from. Aluminum is a top choice due to its lightweight and high-strength characteristics. Other options include magnesium alloys, which are even lighter than aluminum and copper alloys and known for their excellent electrical conductivity.

Applications of Cold Chamber Die-Casting Parts

Cold chamber die casting allows you to create robust parts used in various industries, ensuring a durable and precise outcome every time.

For example, the automotive sector relies on this method for engine blocks and transmission housings, which demand high strength and precision. In the world of aerospace, manufacturers prefer this approach for aerospace parts like components for engines and landing gear, where reliability is key.

Working With Moldiecasting

We boast a team of experienced engineers dedicated to designing durable and low-maintenance molds. Moldiecasting understands that effective mold design is crucial for successful casting, ensuring that your products meet high standards of quality and precision.

The process to get started with Moldiecasting is straightforward and efficient:

- Initial Consultation: You can send your 2D/3D drawings or sample parts, which helps in creating a detailed product blueprint tailored to your specifications.

- Blueprint Approval: After generating the blueprint, you have the opportunity to review and approve it before moving forward, ensuring alignment with your vision.

- Custom Mold Design: Once approved, Moldie begins designing your custom mold using advanced CAD/CAM/CAE software, allowing for seamless integration of your exact requirements.

We employ advanced technology throughout the mold production process. Our quality management system includes high-precision testing equipment, such as three-coordinate and 3D scanners, to guarantee that each mold meets rigorous quality standards.

If you need die-casting parts, please contact us.

Frequently Asked Questions

How do production rates in cold chamber die casting compare to other casting processes?

Cold chamber die casting can exhibit slower cycle times compared to hot chamber casting due to the extra steps of ladling the molten metal and the need to cool the chamber before introducing new metal.

However, it remains highly efficient for high-volume production, often outpacing other methods like gravity die casting or sand casting when it comes to large quantities.