In the machining industry, manufacturers often face parts that are too tough, too thin, or simply too complex for conventional machining methods. That’s exactly where the Electrical Discharge Machining (EDM) proves its value. By removing material with controlled electrical discharges rather than force, this CNC machining technique holds tight tolerances in tool steels, carbides, titanium, and other exotic alloys.

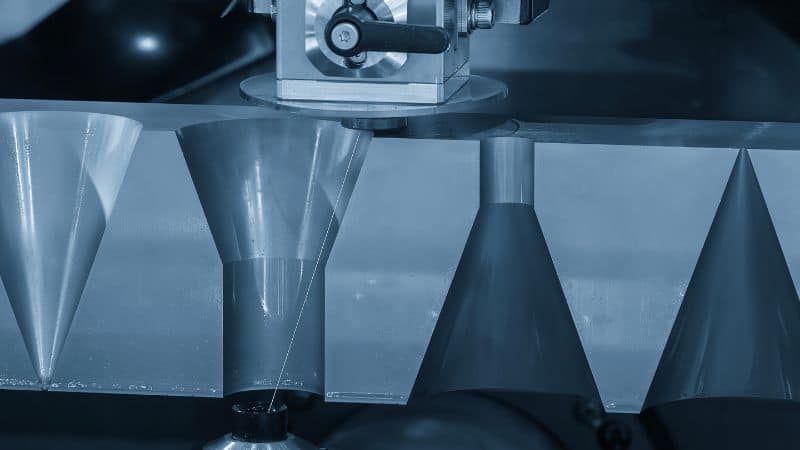

This electric discharge machining process can be categorized into many variations depending on their machining method; the most commonly used ones are wire EDM, sinker EDM and hole drilling EDM.

Wire EDM (WEDM)

Working Principle and Setup

Wire EDM uses a continuously fed electrically charged wire under tension, typically brass or coated brass, as the moving electrode. The wire never contacts the work. Instead, a controlled gap is maintained while the CNC guides the wire along a programmed path. The workpiece sits submerged in deionized water, which acts as the dielectric and efficiently flushes debris. Upper and lower wire guides allow tilting or tapering the wire to create angled features.

The machine’s generator modulates pulse energy, duration, and frequency across roughing and multiple skim passes. Rough cuts prioritize speed, leaving allowance for successive skims that dial in the tolerance and surface finish. Fixturing matters: solid, thermally stable setup, accurate datums, and good flushing paths directly impact accuracy and throughput.

Typical Applications and Materials

Wire EDM machines are typically used for intricate profiles: dies, punches, gears, spline forms, medical components, and complex 2.5D outlines that are difficult or impossible to mill. It excels on hardened tool steels (A2, D2, H13), tungsten carbide, titanium, Inconel, and other superalloys. Common scenarios include cutting die casting dies out of a block, producing precision inserts, sectioning brittle or hardened parts without inducing stress, and creating thin webs or delicate features without distortion.

Advantages and Limitations

- Accuracy and finish: Holding ±0.0001–0.0002″ is routine on stable setups, and surface finishes below 1 μm Ra are achievable with multiple skim passes.

- Minimal mechanical stress: No cutting forces means thin walls and fine details stay intact. Heat-affected zones are small, and recast layers are thin.

- Automation-friendly: Auto-threading, broken-wire recovery, and integrated probing support reliable lights-out runs, especially on longer profiles.

Limitations: The wire must physically access the contour, meaning undercuts or closed cavities are not achievable. Entry requires a start hole unless the start point is located on an edge. Tall parts may need careful flushing strategies to maintain stability and minimize wire erosion and breaks.

Sinker EDM (Die-Sinking/Conventional EDM)

Electrodes, Tooling, and Cavity Formation

Sinker EDM, also known as die sinking, uses a shaped electrode, typically graphite or copper, mounted on a ram. The electrode is placed onto the negative of the cavity, then “sink” it into the work under servo control while spark discharge erodes material. Hydrocarbon-based oil is a common dielectric. Orbiting (small programmed motions like circular or vector orbits) enhances flushing, improves surface finish, and guarantees final dimensions without corner overburn.

Electrode choice makes a huge difference: graphite ensures faster speed, resists heat, and suits larger cavities; copper holds detail well and can yield finer finishes. Experienced manufacturers often stage multiple electrodes: a rougher to hog, a semi-finisher to stabilize walls, and a finisher for tight tolerance and Ra.

Applications, Tolerances, and Surface Finish

Sinker EDM is a go-to option for 3D mold cavities, embosses, ribs, deep pockets, logos, and geometries a straight wire simply can’t access. Tolerances of ±0.0002–0.001″ are realistic depending on size and setup, with surface finishes below 1 μm Ra possible on finishing burns. Because the electrode imparts the geometry, complex blends and freeform shapes are typical in injection molds and die-casting tools.

Advantages and Limitations

- True 3D Capability: Its primary strength is creating blind cavities, undercuts, and complex three-dimensional forms that are impossible for Wire EDM to produce.

- Superior Surface Finish: Capable of producing exceptionally fine surface finishes on intricate contours, often eliminating the need for manual polishing.

Limitations: This constant erosion needs wear compensation in the programming and often requires the fabrication of multiple electrodes for a single job. The volumetric removal rate is generally slower than that of wire EDM, making it less efficient for large-scale stock removal. Additionally, each unique cavity requires a dedicated electrode, and deep, narrow features often present difficulties in dielectric flushing that can compromise both speed and accuracy.

EDM Hole Drilling (Fast Hole/Small Hole EDM)

Process Mechanics

The core of the hole-drilling EDM is a high-speed, rotating tubular electrode, typically made of brass, copper, or wear-resistant copper-tungsten. This hollow tube in most cases acts as the cathode, and the workpiece as the anode. A generator delivers high-frequency electrical pulses across the gap between them, creating a series of controlled sparks that vaporize and erode the material.

Critical to the process is the pressurized dielectric fluid—usually deionized water—which is pumped through the center of the rotating electrode. This serves two vital functions: it forcefully flushes eroded particles out of the narrow gap to prevent short-circuiting, and it deionizes the channel to maintain a stable sparking condition. The rotation of the electrode ensures uniform wear and helps achieve a straighter hole by stabilizing the tube. A servo system constantly adjusts the electrode’s position to maintain the precise spark gap as the hole deepens, enabling the creation of deep, small-diameter holes in hardened materials without the tool deflection that would pose a threat in traditional machining.

Use Cases: Start & Cooling Holes

It is a common practice for manufacturers to rely on EDM drilling for starter holes before wire EDM when the profile begins away from an edge. It’s also the standard for small, high-aspect-ratio cooling holes in turbine blades and vanes, effusion and film-cooling patterns, and precise holes in medical or microfluidic components. Nickel-based superalloys, titanium, and hardened steels are all proper candidates, provided they’re conductive.

Speed, Accuracy, and Limitations

- Speed for Hole Drilling: EDM drilling is exceptionally fast for creating small, deep holes, especially in tough, conductive materials where conventional drilling is slow or impossible. Speed is primarily driven by dielectric pressure, electrode material, and the specific alloy being drilled, allowing for rapid start holes and high-throughput hole patterns.

- Accuracy in Diameter: This process excels at positional accuracy and producing straight, high-aspect-ratio holes with diameters as small as 0.015 inches.

Limitations: The specialization in accuracy also comes with some trade-offs. The surface finish within the holes is generally rougher than that achieved by wire EDM or finishing passes in sinker EDM. Furthermore, the process is limited to mostly straight holes and cannot create bent shapes. Finally, the intense localized heat can leave a recast layer and small burrs at the entry and exit points, which may require secondary finishing for critical applications.

Specialized EDM Machines and Hybrid Processes

Powder-Mixed EDM (PMEDM)

By suspending conductive or semi-conductive powders in the dielectric, this technique can spread the discharge channel, lower energy density, and improve surface finish while reducing tool wear. PMEDM is valuable for finish passes on molds or components where surface integrity matters. It does require filtration and process control to keep concentration consistent.

EDM Milling/Orbiting for 3D Forms

Also called ram EDM milling, this approach uses a small electrode that follows a 3D toolpath, orbiting to create complex forms much like a ball-end mill would, minus cutting forces. It’s effective for delicate or hard-to-reach features and can reduce the number of dedicated electrodes.

Comparing Performance Across Types of EDM Machines

Cutting Speeds and Cycle Time Drivers

- Wire EDM: High relative speed on periphery cuts, especially on long constant-height profiles. Cycle time depends on part height, contour length, number of skims, and flushing.

- Sinker EDM: Medium removal rates: electrode area, orbit strategy, and flushing drive time. Electrode fabrication adds lead time.

- Hole Drilling: Fast for small, deep holes: throughput hinges on electrode wear, dielectric pressure, and alloy.

Accuracy, Tolerances, and Surface Finish (Ra)

- Wire EDM: Very high accuracy: ±0.0001–0.0002″ common, <1 μm Ra achievable with multiple skims.

- Sinker EDM: High accuracy: ±0.0002–0.001″ typical: <1 μm Ra on finishing burns with tuned energy and orbiting.

- Hole Drilling: High positional accuracy for hole locations; surface finish is modest relative to wire/sinker.

Thermal Effects: Recast Layer, Microcracks, and HAZ

All EDM processes produce a thin recast layer with potential microcracks, though the heat-affected zone (HAZ) is generally shallow. This can be mitigated with lower-energy finish passes, optimized pulse parameters, proper flushing, and post-process polishing or light grinding when surface integrity is critical (e.g., fatigue-prone aerospace components).

| EDM Type | Speed | Accuracy | Surface Finish (Ra) | Thermal Effects | Typical Applications

|

|---|---|---|---|---|---|

| Wire EDM | High | Very high | <1 μm | Minimal HAZ, thin recast | Dies, punches, profiles |

| Sinker EDM | Medium | High | <1 μm | Some recast, possible microcracks | Mold cavities, embosses |

| Hole Drilling | Fast/medium | High | Modest | Mostly at entry/exit | Starter holes, cooling holes |

Selection for Your Electrical Discharge Machining Needs

Now that you have learned the different types of EDM, it is time to summarize them for future reference in choosing an EDM machining process. The criteria for the selection can be divided into four aspects.

Geometry and Feature Considerations

- Open contours and through-profiles: Choose Wire EDM. It’s ideal when the wire can access the entire path without undercuts.

- Closed cavities and true 3D forms: Choose Sinker EDM. It creates features a wire can’t reach and transfers complex geometry from an electrode.

- Small, deep, straight holes: Choose EDM drilling. It’s the quickest route to starter holes and high-aspect-ratio cooling features.

Material, Hardness, and Heat-Treatment State

All types of EDM machining require conductivity, but hardness isn’t a limiting factor, as EDM thrives on heat-treated tool steels, carbides, titanium, and nickel alloys. If dimensional stability after heat treatment matters, EDM after hardening eliminates the risk of distortion from machining forces. For carbide or delicate materials, prefer wire or carefully tuned sinker parameters to minimize microcracking.

Batch Size, Cost, and Tooling Economics

- Prototypes and small batches: Wire EDM minimizes upfront tooling, and requires little electrodes, so it’s cost-effective for one-offs and short runs.

- High-volume molds or repeat cavities: Sinker EDM becomes economical when you amortize electrode design and fabrication across many parts. Efficient electrode strategies (rough/finish, shared geometries) cut total cost.

- Hole drilling cells: For recurring cooling-hole patterns, dedicated EDM drilling with automation provides predictable throughput.

Automation, Fixturing, and Process Monitoring

Modern EDM supports lights-out manufacturing. Auto-wire threaders, tool changers, in-process probing, and machine monitoring reduce idle time and scrap. You should prioritize:

- Clean dielectric and stable filtration to maintain spark stability.

- Rigid fixturing with reliable datums to ensure repeatability across skims or electrodes.

- Adaptive generators and corner control to protect accuracy on tight internal radius.

- SPC and logging of parameter sets for traceability on regulated precision machining in the production of medical and aerospace parts.

Conclusion

Electrical Discharge Machining enables complicated designs by utilizing precise CNC machining and overcoming material hardness through complementary methods: wire EDM for profiles, sinker EDM for cavities, and drilling EDM for deep holes.

Equipped with the knowledge from our articles, you will be able to make well-informed decisions in choosing EDM to enhance part quality and competitiveness in advanced manufacturing!

Frequently Asked Questions

Is EDM only for metal? Can I use it on soft, non-hardened materials?

Not exactly. By definition, EDM is exclusively for electrically conductive materials, and insulators like plastics, glass, and normal ceramics or composite materials are out of the question. However, materials like graphite, silicon carbides, titanium diboride and certain polymer composites are also electrically conductive. Despite the fact that they are the niche of EDM, they can also be processed by the machining method.

Also, if the soft materials in question are soft metals like aluminum or mild steel, then EDM is totally viable despite being commonly used on harder materials. It’s just that traditional machining methods are often faster and more cost-effective, unless the geometry is extremely complex or delicate.

How does part size limit EDM?

Each EDM type has inherent size constraints. Wire EDMs are limited by their travel range and tank size. Sinker EDMs are constrained by the work tank and electrode weight capacity. For very large components like a ship’s propeller, dedicated, massive EDM machines would be required.

What causes the recast layer and is it always a problem?

The recast layer is a thin, re-solidified layer of material that was melted but not flushed away by the dielectric fluid. While all EDM creates it, its significance depends on the application. For many molds and tools, it is either inconsequential or can be removed by surface treatment. For highly stressed aerospace components subject to fatigue, it is a critical factor that must be minimized or removed.

Is EDM considered a slow process?

EDM is generally not a high-speed process for bulk material removal compared to conventional machining. Its value is in its capacity for precision machining, not its raw speed. The “effective” speed is high when considering it can eliminate multiple steps (e.g., rough machining, heat-treating, finish machining) and produce a finished part from a hardened blank in a single setup.