Casting quality control is the process used to make sure cast products meet specific standards of shape, size, strength, and surface finish. This step is essential to catch defects and avoid delivering parts that could cause problems later. Every manufacturer relies on careful measurement, inspection, and testing during production.

Careful quality control means that products are safe, reliable, and built to last. Without it, even the smallest error in the casting process can lead to expensive failures. Today at Moldie, you can learn what techniques are used to maintain quality and why they matter.

Key Aspects of Casting Quality Control

Casting quality control helps ensure products meet strict requirements for size, strength, and reliability. Several methods work together to identify and prevent defects, check measurements, and control every stage of the casting process.

Fundamental Quality Control Measures

Quality assurance in casting begins with checking raw materials and continues through each step of production. Workers monitor material composition, pouring temperature, and mold quality. Visual inspection helps find surface defects like cracks, pores, or slag.

Material samples may undergo chemical and mechanical testing to verify strength and composition. Nondestructive testing methods, such as X-ray or ultrasonic inspection, can uncover hidden flaws. Each step reinforces quality for castings that must be reliable in real use.

Dimensional Inspection and Accuracy

Accurate dimensional inspection ensures products fit and work properly. Common tools include calipers, micrometers, and coordinate measuring machines (CMM). CMMs are highly precise and allow for automated checks of complex parts.

Inspectors measure features like thread pitch, hole size, and straightness. Measurements are compared to design drawings using tolerance tables. Monitoring shrinkage rate and tool wear helps keep dimensions within acceptable limits.

Process Control and Monitoring

Process control aims to prevent defects by supervising key variables such as temperature, timing, and material flow. Modern foundries often use Manufacturing Execution Systems (MES) to track each batch and process parameter.

By controlling steps like mold preparation and cooling rates, manufacturers reduce risks of shrinkage, cracks, and other casting flaws. Regular process reviews and equipment maintenance help ensure stability and consistent results.

Casting Inspection and Testing Methods

Effective casting inspection is necessary for identifying internal and external defects, confirming dimensions, and ensuring each part meets quality standards.

Visual Inspection

Visual inspection is the most basic method used in casting inspection. It involves examining the surface of the casting with the naked eye or with magnifying tools to identify obvious defects. Common problems spotted include surface cracks, pits, warping, and incomplete filling.

This method is fast and low-cost, making it the first step in quality control. Inspectors look for signs of excess flash, roughness, or visible inclusions. Lighting and viewing angles are important to spot small surface flaws. Any area with unclear results may be marked for further, more detailed testing.

Visual inspection is often combined with simple measurement tools. Straight edges, calipers, and gauges can verify dimensions. While it cannot find hidden defects inside the casting, it remains essential for ensuring the outward quality of each product before more advanced techniques are applied.

Pros:

- Quick and easy

- No special equipment needed

- Helps find obvious surface defects

Cons:

- Cannot find internal problems

- May miss small cracks

Non-Destructive Testing

Non-destructive testing (NDT) methods allow foundries to examine castings for hidden defects without causing damage. These techniques can reveal both surface and internal issues, making them important in quality assurance for critical parts.

Key NDT methods include:

- Dye Penetrant Inspection (DPI): A colored or fluorescent dye is applied to the surface, which seeps into cracks. After removing excess dye, an inspector checks for traces indicating flaws.

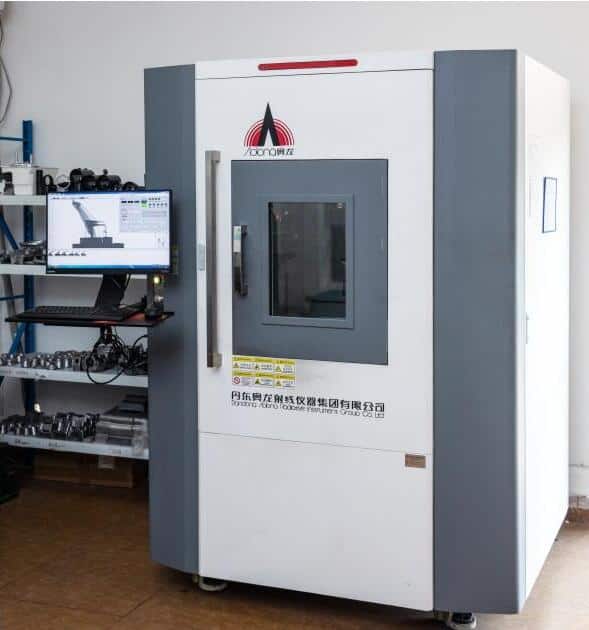

- Radiographic Testing (RT): X-rays or gamma rays pass through the casting, producing images that show internal voids or inclusions.

- Ultrasonic Testing (UT): High-frequency sound waves are sent into the casting, which bounce back from internal interfaces such as voids, producing signals that reveal hidden flaws.

NDT methods are selected based on casting size, material, and required defect detection level. They provide a detailed view that supports decisions about part acceptance or rejection. Though more costly than visual checks, NDT increases reliability, especially where safety and performance are critical.

Magnetic Particle Inspection

Magnetic Particle Inspection (MPI) is used to find surface and near-surface flaws in ferromagnetic castings. The casting is first magnetized using an electric current or strong magnet. While under magnetization, fine iron particles—either dry or suspended in liquid—are spread over the surface.

If there are cracks or discontinuities, the magnetic field will rapidly change at these points, attracting the particles to the defect and forming a visible indication. This makes MPI valuable for detecting very thin or tight cracks that other methods may miss.

MPI is often used after visual checks but is limited only to materials that can be magnetized, such as iron or steel alloys. It is highly sensitive for finding surface-breaking defects and is frequently used for automotive, aerospace, and structural components. Interpretation of results requires trained operators, as false indications can occur if the surface is dirty or rough.

Strengths:

- Detects surface and near-surface flaws

- Fast and reliable on ferrous materials

Weaknesses:

- Only for ferromagnetic metals

- Surface preparation may be needed

Ultrasonic Testing

Ultrasonic Testing (UT) is a key NDT method for finding internal defects in metal castings. It uses high-frequency sound waves generated by a probe placed on the casting surface. These waves travel through the material and reflect back from boundaries or flaws within the casting.

By measuring the time and strength of returned signals, inspectors can determine the presence, size, and location of internal defects such as voids, inclusions, or shrinkage cavities. UT is effective even in thick or dense castings, which makes it suitable for engine blocks, gears, and structural components.

The method is clean and does not harm the casting. Skilled technicians can interpret the ultrasonic signals using digital displays or charts. A limitation is that surface roughness or complex shapes can reduce accuracy, so good surface contact is required.

Advantages:

- Sensitive to small, hidden defects

- Works on many casting sizes and materials

- Gives immediate results in digital form

Limitations:

- Requires trained operators

- Surface must be accessible and relatively smooth

Destructive Testing and Certification

Destructive testing reveals how castings perform under real stress, heat, and impact. These tests, along with industry certification, help verify mechanical properties and ensure products meet set standards.

Tensile Testing

Tensile testing measures how much a casting can stretch or resist breaking when pulled. In this process, a sample from the casting is pulled apart in a controlled machine.

Key data collected includes:

| Property | Description |

|---|---|

| Ultimate strength | The maximum force before breaking |

| Yield strength | The force where permanent change appears |

| Elongation | How much the sample stretches |

By studying these results, foundries check if the metal can handle required loads. This helps set safe working limits for products.

Tensile testing is essential for parts that will hold weight, bend, or pull during use. Results also support engineers in choosing alloys and setting quality benchmarks.

Hardness Testing

Hardness testing shows how well a casting surface resists scratches, pressing, or wear. It uses a device to press a hard tip into the metal and measures the depth or size of the mark.

Common methods include:

- Brinell Hardness Test

- Rockwell Hardness Test

- Vickers Hardness Test

Each method uses a different scale and technique, but all help identify if a casting is strong enough to avoid dents or surface wear.

Good hardness means a part should last longer and resist damage from tools or moving parts. Testing is quick and often done at several locations on a single casting for accurate results.

Impact Testing

Impact testing finds out how much force a casting can take before fracturing when hit suddenly. The most used test is the Charpy impact test, where a notched sample is struck with a swinging hammer.

The energy absorbed before the sample breaks gives a clear measure of toughness.

Results show if a casting can stand up to shocks, drops, or crashes without shattering. Impact strength is important in parts that might face accidental impacts or extreme conditions.

Low impact strength can lead to dangerous failures, so this test is vital for safety-critical castings.

Certification and Standards

Certification ties test results to industry standards. Organizations like ASTM, ISO, and others set minimum values for mechanical properties so castings perform as needed.

Foundries keep records of testing, material grades, and traceability for every batch. Traceability links a final product to its raw materials, processing steps, and quality checks.

Audits may verify if proper destructive testing was done. Certification builds trust with customers and helps products move through supply chains by meeting local or global requirements.

Frequently Asked Questions

Casting quality depends on clear standards, strict processes, and accurate records. Each area helps manufacturers find and control possible issues in metal parts.

How is the quality level of castings categorized and measured?

Castings are graded based on factors like size, shape, surface finish, material strength, and the presence of defects. Measurement tools can include gauges, hardness testers, and digital imaging systems.

The results are compared to industry or customer standards. Common grading systems may use codes or numbers to show the types and severity of any flaws.

What steps in the casting process are most critical for ensuring quality?

Mold preparation is important, since problems here can cause surface or shape defects. Melting and pouring must be done at the right temperature to avoid weak spots or porosity.

Cooling and solidification control are also key steps. Uneven cooling can lead to cracks or warping. Inspection after casting helps spot any remaining problems before shipping.

What documentation is typically required for casting quality control?

Manufacturers keep process sheets, inspection reports, and test records for every batch of castings. These records may contain measurements, test results, and notes from visual checks.

Traceability is often supported by batch numbers or barcodes. Maintaining this documentation helps prove that parts meet required standards and makes it easier to solve any quality issues.