Hot chamber die casting is a casting method where molten metal is injected directly into a mold using a built-in chamber, making it ideal for alloys with lower melting points.

Understanding how the process works, which materials it uses, and how it differs from cold chamber die casting provides a clear picture of why it remains so widely used. Exploring its applications and machine components also shows how this method continues to shape industrial production today.

Overview of Hot Chamber Die Casting

Hot chamber die casting is a manufacturing process that uses molten metal injected under pressure into a die to form precise parts. It is best suited for metals with low melting points and is valued for speed, accuracy, and consistent surface finish.

What Is Hot Chamber Die Casting?

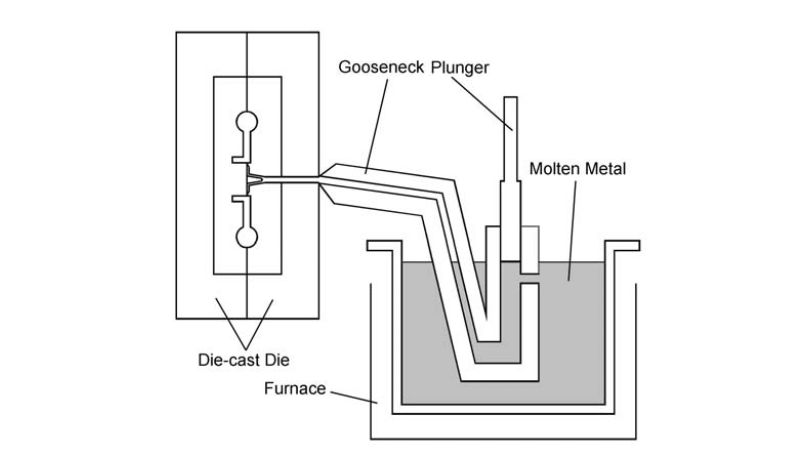

Hot chamber die casting is a process where the injection system is placed directly in a furnace holding molten metal. A plunger forces the liquid metal through a nozzle into a steel die, where it solidifies into the desired shape. This method works well for alloys like zinc, magnesium, and lead-based materials. These metals melt quickly and flow easily, which makes the process fast and efficient.

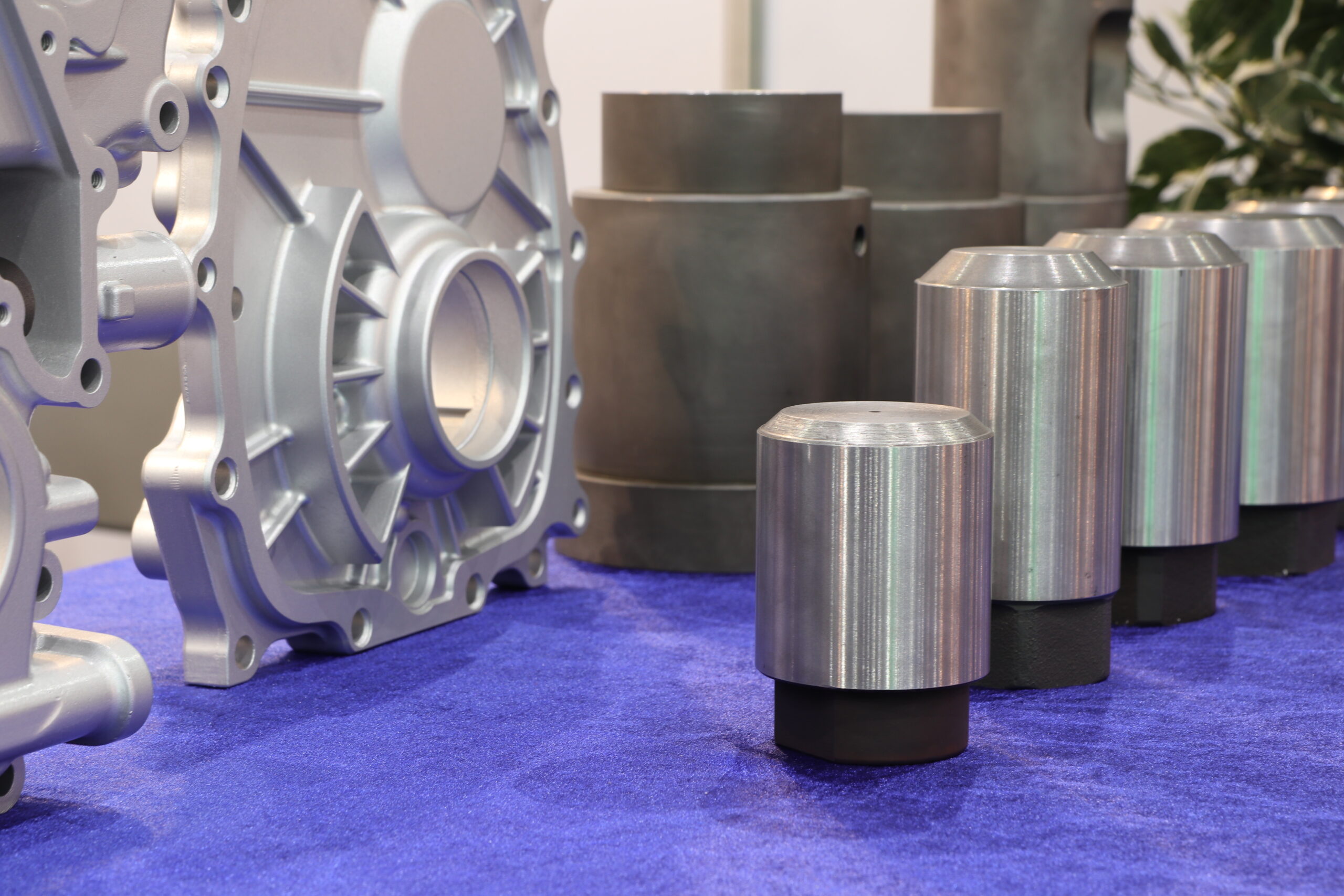

In practice, manufacturers use hot chamber machines for small to medium-sized parts that require fine detail and smooth surfaces, such as automotive components, appliance housings, and electronic connectors.

Key Advantages of Hot Chamber Die Casting

Despite being the more traditional option compared to cold chamber die casting, hot chamber die casting is still a well-established casting method. This process offers several benefits that make it popular in mass production, where steady performance is the key to success.

One of the most important advantages is speed. The direct connection between the injection system and molten metal reduces handling time, resulting in faster cycles.

Another advantage is precision. The high pressure injection fills the die completely, creating high-quality parts with tight tolerances and excellent surface finishes. This reduces the need for secondary machining.

Hot chamber die casting is also cost-effective for large runs. The reusable dies and rapid cycles lower the per-part cost. Additionally, the process allows for thin walls and complex shapes, which helps reduce material use.

The method also provides consistency. Each part produced is nearly identical, which is critical for industries that require interchangeable components.

Limitations of Hot Chamber Die Casting

Despite its strengths, hot chamber die casting has certain limits. The most significant is the restriction on material choice. Only metals with low melting points, such as zinc and magnesium, can be used. Higher-melting-point alloys like aluminum cannot be cast with this method.

Tooling costs can also be high. Although dies are durable, they require significant upfront investment, which may not be practical for small production runs.

Part size is another limitation. Hot chamber machines are better suited for smaller components, and producing large or heavy parts is not efficient with this process.

Finally, while surface finish is generally good, some parts may still require minor finishing work to remove flash or sharp edges created during casting.

Key Components of Hot Chamber Die Casting Machines

A hot chamber die casting machine relies on several integrated parts that work together to inject molten metal into a mold with speed and precision. Each component plays a specific role in controlling temperature, pressure, and metal flow to produce consistent castings.

Hot Chamber and Furnace

The hot chamber holds the molten metal and keeps it at a stable temperature for casting. It is directly attached to the furnace, which melts the alloy and maintains it in liquid form. This design reduces handling steps and shortens cycle times compared to external melting systems.

The furnace is usually built into the die casting machine. It is lined with heat-resistant material to withstand continuous exposure to molten zinc, magnesium, or other low-melting-point alloys.

A key advantage of this setup is that the molten metal is always available inside the machine. This allows faster injection cycles and reduces the risk of contamination or temperature loss during transfer.

Plunger and Gooseneck Mechanism

The plunger and gooseneck mechanism delivers molten metal from the hot chamber into the die cavity. The gooseneck is a tube-shaped channel that connects the hot chamber to the die. It is submerged in the molten metal, ensuring a direct supply.

The plunger operates inside the gooseneck. When activated, it pushes molten metal upward through the nozzle under controlled pressure. This action must be precise to avoid defects such as air entrapment or incomplete filling.

Different alloys may require adjustments to plunger speed and pressure. For example, zinc often needs higher injection speeds to ensure the metal fills thin sections of the die without solidifying too early.

Die and Die Cavity

The die is a hardened steel mold that shapes the final part. It consists of two halves: the fixed die half, attached to the casting machine, and the moving die half, which opens and closes during each cycle.

The die cavity is the hollow space inside the die that defines the geometry of the casting. It must be carefully designed to account for shrinkage, flow paths, and ejection needs.

Cooling channels are often built into the die to regulate temperature and solidification rates. Proper cooling prevents defects such as warping or surface irregularities and extends die life during high-volume production.

Hot Chamber Die Casting Process

This process uses an integrated furnace and injection system to handle molten metal directly inside the machine. It relies on controlled pressure to fill the die quickly and produces parts with consistent shapes, smooth surfaces, and short cycle times.

Step-by-Step Process

The hot chamber die casting process begins with molten metal stored in an attached furnace. The furnace keeps the metal at a stable temperature, ready for injection.

A “gooseneck” mechanism draws the molten metal into a cylinder. Once filled, a plunger forces the metal through a nozzle and into the die cavity.

The die, made of hardened steel, shapes the molten metal as it flows in. After the cavity is filled, the metal begins to cool and harden within the mold.

When the solidification reaches a stable state, the die opens. Ejector pins push the finished casting out of the mold. The cycle then resets, and the process repeats for the next part.

Role of Pressure and Solidification

Pressure plays a central role in ensuring the molten metal fills every the entire die. Without adequate force, the metal would not reach thin walls or small features.

Typical injection pressures range from 1,500 to 4,500 psi depending on the alloy and part size. This pressure prevents air pockets and improves surface finish.

Solidification occurs while the metal remains under pressure. This reduces shrinkage and strengthens the final casting. Uniform cooling is important because uneven solidification can cause defects such as warping or porosity.

The die often includes cooling channels to control how fast the metal solidifies. This balance between pressure and cooling ensures the casting meets dimensional and mechanical requirements.

Cycle Times and Efficiency

One of the main advantages of hot chamber die casting is its short cycle time. Since the furnace is built into the machine, molten metal is always available for the next shot.

Typical durations range from 15 to 60 seconds, depending on part complexity and size. This makes the process suitable for high-volume production of small to medium-sized parts.

Efficiency also comes from reduced handling. Operators do not need to transfer molten metal between machines, which lowers energy use and improves safety.

The process works best with low-melting-point alloys such as zinc, tin, and magnesium. These alloys allow faster cycles because they heat and cool more quickly than high-melting-point metals.

Applications and Industry Uses

Hot chamber die casting supports the production of precise metal components where speed, consistency, and smooth surface finish matter. It is most effective with alloys that have lower melting points, making it a common choice in industries that require high-volume manufacturing and reliable dimensional accuracy.

Automotive Components

The automotive industry uses hot chamber die casting to create small and medium-sized parts from zinc and magnesium alloys. These metals allow for thin walls and complex shapes that remain strong yet lightweight.

Common parts include carburetor housings, transmission cases, brackets, and engine components. These parts benefit from the process’s ability to maintain tight tolerances, which supports proper fit and function in high-performance systems.

The smooth surface finish achieved reduces the need for secondary machining. This lowers cost while keeping production speed high. Since automotive manufacturing demands both accuracy and durability, hot chamber die casting offers an efficient balance between quality and output.

Consumer Electronics and Electrical Enclosures

Electronics manufacturers rely on hot chamber die casting for compact housings and enclosures. Zinc alloys are often used because they provide strength while allowing thin walls and fine details.

Examples include smartphone frames, laptop hinges, connectors, and protective casings. These parts require dimensional accuracy to fit sensitive electronic assemblies without gaps or misalignment.

The process also ensures a clean surface finish, which is important for both function and appearance. Electrical enclosures, such as switch housings and small motor components, benefit from the material’s ability to resist wear and provide shielding against interference.

Other Industrial Applications

Beyond automotive and electronics, hot chamber die casting supports industries that need durable, low-melting-point metal components at scale. Hardware products like door handles, locks, and appliance parts are often produced this way due to the process’s efficiency.

Medical devices also use zinc die cast parts such as pump housings and precision connectors. These require consistent dimensional accuracy for reliable performance.

In instrumentation and machinery, the method produces gears, levers, and housings where repeatability and smooth finishes reduce the need for added processing. This makes it a practical choice for manufacturers seeking both cost control and dependable results.

Frequently Asked Questions

Which metals are typically processed in hot chamber die casting machines?

This method is commonly used for zinc, magnesium, and other low melting point alloys. These metals flow easily into molds and solidify quickly, making them well-suited to the process. Aluminum and copper alloys are generally avoided due to their higher melting points.

Can hot chamber die casting be used for high melting point metals?

No, it is not suitable for high melting point metals like aluminum, brass, or steel. The constant contact between the injection system and molten metal would damage the equipment at those temperatures. Cold chamber casting is the preferred method for such materials.

What are the common defects associated with hot chamber die casting?

Typical defects include porosity, cold shuts, and surface blemishes. These issues often result from trapped air, incomplete filling, or improper temperature control. Careful process monitoring helps reduce the occurrence of these problems.