Aluminum alloy die casting is a manufacturing process that produces high-quality, high-tolerance parts by injecting molten aluminum alloy under high pressure into a precision-engineered die.

This method utilizes various aluminum alloys and is especially efficient for producing intricate, complex, and highly detailed components that faithfully replicate the original design specifications.

Aluminum Alloys for Die Casting

Aluminum alloy die casting typically begins shortly after the aluminum is extracted. These die castings are widely valued for being lightweight while maintaining the ability to withstand the high temperatures inherent to the die casting process.

Once aluminum alloy die casting is identified as suitable for a project, selecting an appropriate aluminum alloy becomes essential.

Major Aluminum Alloys

Although aluminum is abundant, its extraction is complex. To enhance its properties, aluminum is often alloyed with other metals. Selecting the correct alloy is critical for a successful die casting project.

Common aluminum alloys include:

-

AA-8000: Used for building wire per the National Electrical Code.

-

Zamak: An alloy of zinc, aluminum, magnesium, and copper.

-

Alclad: Aluminum sheet with a high-purity aluminum surface bonded to a high-strength core.

-

Duralumin: Primarily copper and aluminum.

-

Silumin: Aluminum-silicon alloy commonly used in die casting.

-

Magnalium: Aluminum-magnesium alloy.

-

And others such as Alnico, Al-Li, Magnox, Nambe, Birmabright, Hindalium, and Titanal.

Aluminum alloys are commonly identified by a four-digit numbering system:

-

1000 series: High-purity aluminum (99.5% or higher).

-

2000 series: Copper-based; heat-treatable for high strength.

-

3000 series: Manganese-based; offers good workability and corrosion resistance.

-

4000 series: Silicon-added; lowers melting point without brittleness.

-

5000 series: Magnesium-based; offers marine-grade corrosion resistance and weldability.

-

6000 series: Magnesium and silicon; form magnesium silicide for good strength and corrosion resistance.

-

7000 series: Zinc-based; very strong and heat-treatable.

-

8000 series: Includes other miscellaneous elements.

Properties of Aluminum Alloys in Die Casting

Selecting an alloy for die casting requires careful evaluation of its characteristics, which directly affect production and part performance:

-

Die Soldering Resistance: Prevents the alloy from sticking to the die walls, reducing damage and maintenance.

-

Hot Cracking Resistance: Minimizes cracking defects during solidification.

-

Wear Resistance: Important for parts subjected to friction.

-

Corrosion Resistance: Varies by alloy; critical for harsh environments (e.g., 5000 series in marine applications).

-

Machinability and Surface Treatment: Affects how easily the die-cast part can be machined or finished post-casting.

No single aluminum alloy is ideal for all applications, so selection must be based on specific project requirements.

Heat Treatment of Aluminum Die Cast Alloys

Heat treatments can enhance mechanical properties such as strength and hardness:

-

Annealing: Heats the cast part to recrystallize the structure, improving workability.

-

Solution Heat Treatment: Involves heating followed by quenching to maintain elemental distribution.

-

Aging: Further enhances properties after quenching, depending on the required timeframe.

Machining and Finishing Options

Aluminum die castings accept a variety of finishes due to their naturally reflective surface:

-

PVDF coatings

-

Powder coatings

-

Liquid paints

-

Anodizing

-

Heat treating

-

Cold working

-

Rolling

The natural oxide layer can be enhanced through anodizing for improved durability and appearance.

Advantages of Aluminum Alloy Die Casting

Key benefits include:

-

Fully recyclable

-

High pressure tightness

-

Excellent thermal and electrical conductivity

-

Superior corrosion resistance

-

Good creep resistance

-

High dimensional stability

Additional advantages depend on the specific alloy series selected.

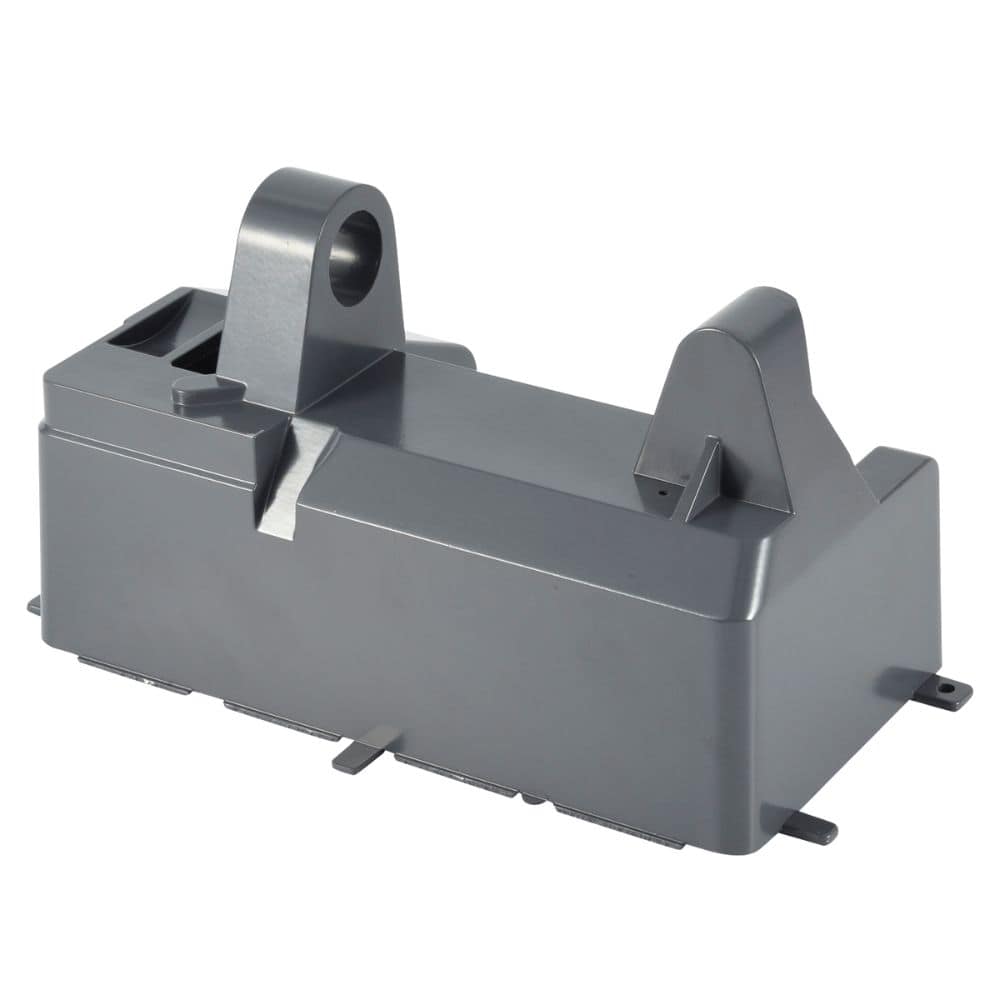

Applications of Aluminum Alloy Die Casting

Die-cast aluminum alloys are used across industries due to their versatile properties:

-

Automotive: Reducing engine and body panel weight to improve fuel efficiency.

-

Hand Tools: Providing RFI/EMI shielding, durability, and rigidity.

-

Electronics: Housings and connectors benefiting from shielding and electrical performance.

-

Telecom & IT: Infrastructure and networking equipment.

-

Aerospace: Various aircraft components.

Select an aluminum alloy whose properties best match the application’s demands for optimal performance.

Specifications Overview

| Mold Base | LKM C50 + P20 for AB, Cast iron etc. |

|---|---|

| Inserts(cavity and core) | Dievar, H13, 8407, 1.2344 or the material you required |

| Standard | HASCO, DME, MISUMI, PUNCH and so on |

| Product Material | ADC12, ADC14, A360, A380, AlSi9Cu3 and so on |

| Mold Treatment | Heat Treatment >HRC45 |

| Product Surface | Sand blasting, Powder coated, Painting, Anodizing, etc |

| Shape & Color | Can be design according to your needs |

| Process | High Pressure Die Casting |

| Certificated | ISO 9001:2015 Certificated |

Trade Information

| MOQ | 1 set |

|---|---|

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |