What is Cast Aluminum?

Aluminum is a versatile metal used in various industries, from automotive and aerospace to construction and consumer goods. Its lightweight nature, strength, and resistance to corrosion make it an attractive choice for numerous applications.

However, cast aluminum stands out due to its unique properties and manufacturing process, which allow for the creation of complex shapes and enhanced performance characteristics.

In this comprehensive blog post, we’ll explore the properties of cast aluminum, the differences between cast aluminum and regular aluminum, and its common applications across various industries.

What Are the Different Types of Aluminum Casting Processes?

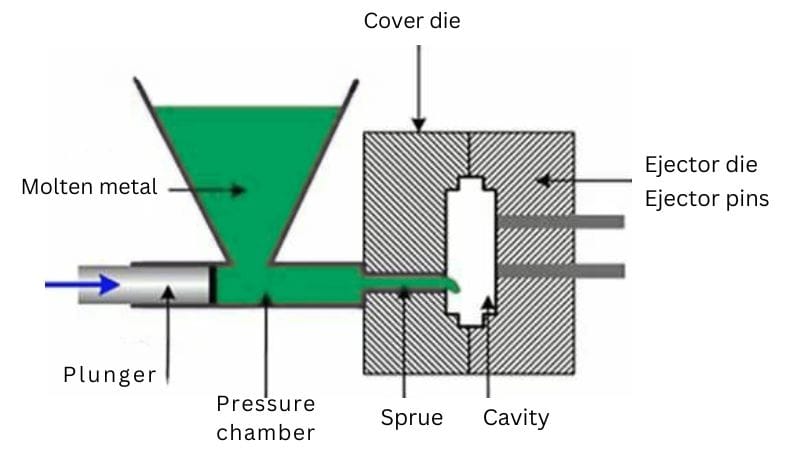

1. Die Casting

Die casting is a high-pressure casting process that involves injecting molten aluminum into a steel mold (die) at high speeds, creating detailed and accurate parts with smooth surfaces.

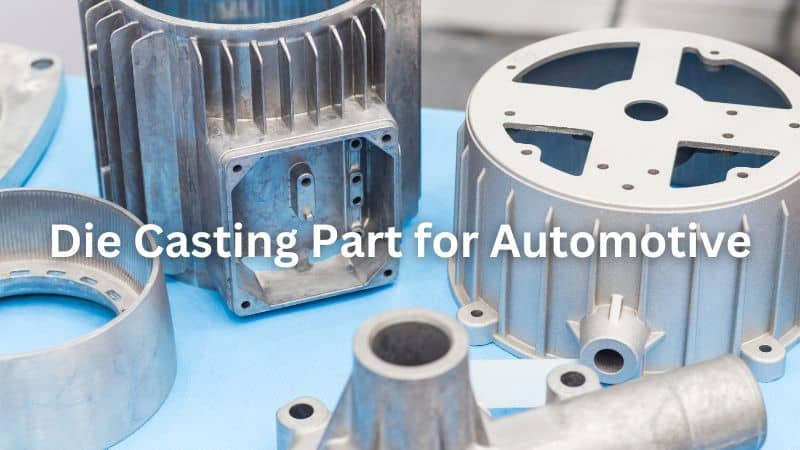

Die casting is suitable for producing high volumes of small to medium-sized parts with tight tolerances, making it a popular choice for automobile, electronics, and consumer goods industries.

2. Permanent Mold Casting

Also known as gravity die casting, this process uses a reusable metal mold to shape the molten aluminum. The mold is typically made of steel and consists of two halves that are clamped together.

Permanent mold casting is suitable for producing medium to large-sized parts with good finish and dimensional accuracy, such as automotive wheels, cylinder heads, and machine tool components.

3. Shell Mold Casting

Shell mold casting involves creating a thin, shell-like mold using a mixture of sand and a thermosetting resin binder. The sand mixture is compacted around a heated metal pattern, causing the resin to cure and form a rigid shell.

Shell mold casting is suitable for producing small to medium-sized parts with good finish and dimensional accuracy, such as valve bodies, impellers, and gears.

4. Lost Foam Casting

Lost Foam Casting uses a polystyrene foam pattern to create the mold, which is then vaporized when molten aluminum is poured in. It allows for the production of complex parts with intricate internal features, such as engine manifolds, cylinder heads, and oil pans.

5. Sand Casting

Sand casting is a traditional and adaptable technique for creating molds by packing sand around a pattern that mirrors the final shape of the object. Sand casting is ideal for producing large, complex parts with intricate details, such as engine blocks, pump housings, and industrial equipment components.

6. Vacuum Die Casting

Vacuum die casting aims to evacuate air from the die cavity before injecting the molten aluminum, reducing porosity and improving mechanical properties. It is particularly useful for producing parts with thin walls and complex geometries, such as electronic housings, heat sinks, and medical device components.

7. Investment Casting

Investment casting, also known as lost-wax casting, employs a disposable wax pattern to create a ceramic mold, which is capable of producing parts with excellent surface finish, tight tolerances, and intricate details. It is suitable for aerospace, medical, and jewelry applications.

8. Ceramic Mold Casting

Ceramic mold casting is similar to investment casting but uses a ceramic mold instead of a wax pattern. Ceramic mold casting offers high-temperature resistance, excellent surface finish, and the ability to produce complex shapes, making it suitable for high-performance applications in the aerospace and automobile industries.

Cast Aluminum vs. Aluminum

While cast aluminum and regular aluminum are both derived from the same base metal, they have distinct differences in their properties, manufacturing processes, and applications. Understanding these differences is crucial to decide which material to use for a specific project or product.

- Composition:

Cast aluminum typically contains a higher percentage of alloying elements, such as silicon, magnesium, or copper, compared to regular aluminum. These additives are introduced during the casting process to enhance the metal’s castability, strength, and other desirable properties.

On the other hand, regular aluminum may have lower amounts of alloying elements or be relatively pure, depending on its intended use.

- Manufacturing Process:

The primary difference between cast aluminum and regular aluminum lies in their manufacturing processes. Cast aluminum is produced by pouring molten aluminum into a mold, allowing it to cool and solidify.

This process enables the creation of complex shapes and intricate designs that would be difficult or impossible to achieve through other fabrication methods. Regular aluminum, in contrast, is typically shaped using processes such as extrusion, rolling, or forging, which involve applying pressure to the metal to create the desired form.

- Strength and Durability:

Cast aluminum generally exhibits higher strength and stiffness compared to regular aluminum. The casting process and the presence of alloying elements contribute to the improved mechanical properties of cast aluminum.

This makes it an ideal choice for applications that require structural integrity and durability, such as automotive components, industrial equipment, and aerospace parts. Regular aluminum, while still strong and lightweight, may not offer the same level of strength and rigidity as cast aluminum.

- Corrosion Resistance:

Both cast aluminum and regular aluminum offer excellent corrosion resistance, making them suitable for use in harsh environments. However, cast aluminum often demonstrates superior corrosion resistance, especially when alloyed with elements like silicon or magnesium.

The enhanced corrosion resistance of cast aluminum is particularly valuable in applications where the metal is exposed to moisture, salt, or other corrosive substances.

- Cost:

The cost of cast aluminum is generally higher than that of regular aluminum. The casting process itself, along with the additional alloying elements used, contributes to the increased cost. However, the higher cost of cast aluminum is often justified by its improved properties, such as strength, durability, and corrosion resistance.

Additionally, the ability to create complex shapes through casting can reduce the need for post-processing, offsetting some of the initial cost differences.

- Applications:

Cast aluminum finds extensive use in industries such as automotive, aerospace, manufacturing, and construction. Its ability to be molded into intricate shapes, combined with its strength and lightweight nature, makes it ideal for producing components like engine parts, wheel rims, structural elements, and decorative pieces.

On the other hand, regular aluminum is more commonly used in applications where simple shapes and lower costs are prioritized, such as in packaging, electrical wiring, and consumer goods.

Common Applications of Cast Aluminum:

- Medical Industry: Surgical instruments, medical device housings, and rehabilitation equipment.

- Automotive Industry: Engine parts, transmission components, wheel rims, suspension parts, and structural elements.

- Culinary Industry: Cookware, bakeware, and kitchen utensils.

- Aerospace Industry: Fuel system parts, hydraulic components, structural elements, and landing gear components.

- Electronics Industry: Heat sinks, electronic housings, and enclosures for various devices.

- Industrial Equipment: Pump housings, valve bodies, gears, and machine tool components.

- Building and Construction: Architectural elements, window frames, and decorative components.

- Consumer Goods: Furniture parts, sporting goods equipment, and household appliances.

Cast aluminum is a versatile and valuable material that offers unique properties over regular aluminum. With its strength, corrosion resistance, design flexibility, and lightweight nature, cast aluminum finds applications in various industries, from automotive and aerospace to medical and culinary.

The different casting processes available, such as die casting, sand casting, and investment casting, allow for the production of parts with specific properties and geometries, catering to the diverse needs of various applications.

By understanding the properties, aluminum casting types, and common applications of cast aluminum, manufacturers can make informed decisions when selecting materials for their projects, ensuring optimal performance, cost-effectiveness, and product quality.

As technology advances and new alloys are developed, the potential applications of cast aluminum are likely to expand further, cementing its position as a crucial material in modern manufacturing.