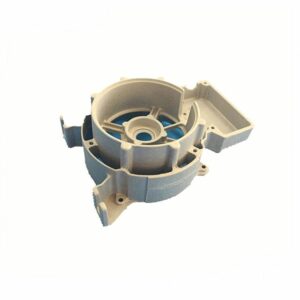

Durable, High Quality, and Precise – Stainless Steel Heat Sink from Moldie

Stainless steel heat sinks are vital components in offering heat dissipation for a wide range of applications. Manufactured with precision engineering and adherence to high-quality standards, these heat sinks at Moldie are ideal for industries such as electronics, automotive, and aerospace, where efficient thermal control is crucial.

Our heat sinks are produced using advanced High Pressure Die Casting processes, ensuring exceptional dimensional accuracy and consistency. Built on a durable LKM C50 + P20 mold base or cast iron, the products feature high-strength inserts made from premium materials like Dievar, H13, 8407, or 1.2344, with flexibility to accommodate custom material requirements. Designed to comply with industry standards such as HASCO, DME, MISUMI, and PUNCH, these heat sinks are tailored for both reliability and compatibility across various applications.

Crafted using high-quality alloys like ADC12, ADC14, A360, A380, and AlSi9Cu3, the heat sinks undergo rigorous heat treatment (>HRC45) to enhance durability and thermal performance. The product surface can be customized with options such as sand blasting, powder coating, painting, or anodizing, delivering the desired finish and added protection. Furthermore, the shape and color of the heat sink can be fully customized to meet specific client requirements, ensuring both functional and aesthetic adaptability.

Certified to ISO 9001:2015, these stainless steel heat sinks represent the perfect balance of innovation, quality, and customization—making them an excellent choice for effective heat management solutions across diverse industries.

Parameters of Product

| Mold Base | LKM C50 + P20 for AB, Cast iron etc. |

|---|---|

| Inserts(cavity and core) | Dievar, H13, 8407, 1.2344 or the material you required |

| Standard | HASCO, DME, MISUMI, PUNCH and so on |

| Product Material | ADC12, ADC14, A360, A380, AlSi9Cu3 and so on |

| Mold Treatment | Heat Treatment >HRC45 |

| Product Surface | Sand blasting, Powder coated, Painting, Anodizing, etc |

| Shape & Color | Can be design according to your needs |

| Process | High Pressure Die Casting |

| Certificated | ISO 9001:2015 Certificated |

Trade Information

| MOQ | 1 set |

|---|---|

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port |