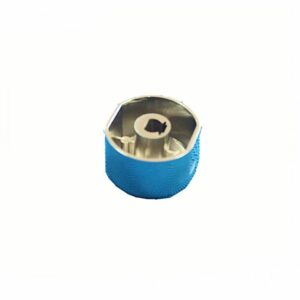

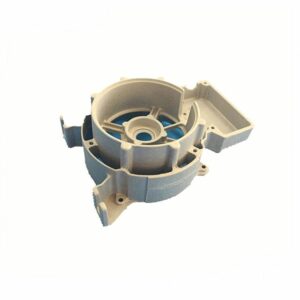

Discover precision and durability with Moldie’s aluminum die casting caps, offering exceptional quality and customization to meet diverse manufacturing requirements.

Our molds are constructed using robust LKM C50 + P20 materials, reinforced with cast iron, and feature high-quality inserts such as Dievar, H13, and 8407. These components ensure compatibility with commonly used materials, including ADC12 and A360 alloys, resulting in superior performance and prolonged durability. Each mold undergoes rigorous heat treatment, achieving a hardness level exceeding HRC45, ensuring long-lasting reliability in industrial applications.

Manufactured to align with globally recognized standards like HASCO, DME, and MISUMI, these machine caps guarantee precision and compliance for varied applications. Furthermore, they are finished with advanced techniques such as anodizing and powder coating, allowing for customizable designs and colors tailored precisely to your business needs.

Key Features

Material Composition: LKM C50 + P20 base with cast iron reinforcement and premium inserts like Dievar, H13, and 8407.

Industry Standards: Fully compliant with HASCO, DME, and MISUMI guidelines.

Durability: Heat-treated for resilience with hardness above HRC45.

Custom Options: Flexible designs, sizes, and finishes such as anodizing and powder coating.

With an ISO 9001:2015 certification as proof of quality excellence, our molds promise efficient production processes

Contact us today to elevate your manufacturing process with our expertly crafted mold for aluminum casting!

Trade information

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port |