High quality materials

As a professional die casting parts manufacturer, our die cast knobs are build our molds on a robust foundation of LKM C50 and P20 steel, reinforced with cast iron for superior stability and longevity.

Our core and cavity inserts are precision-crafted from high-performance steels like Dievar, H13, and 8407, tailored to your specific requirements. Adherence to international standards such as HASCO, DME, and MISUMI ensures consistent quality and compatibility across every production run.

We utilize premium aluminum alloys and apply advanced heat treatment processes, achieving hardness levels above HRC45 to enhance wear resistance and durability.

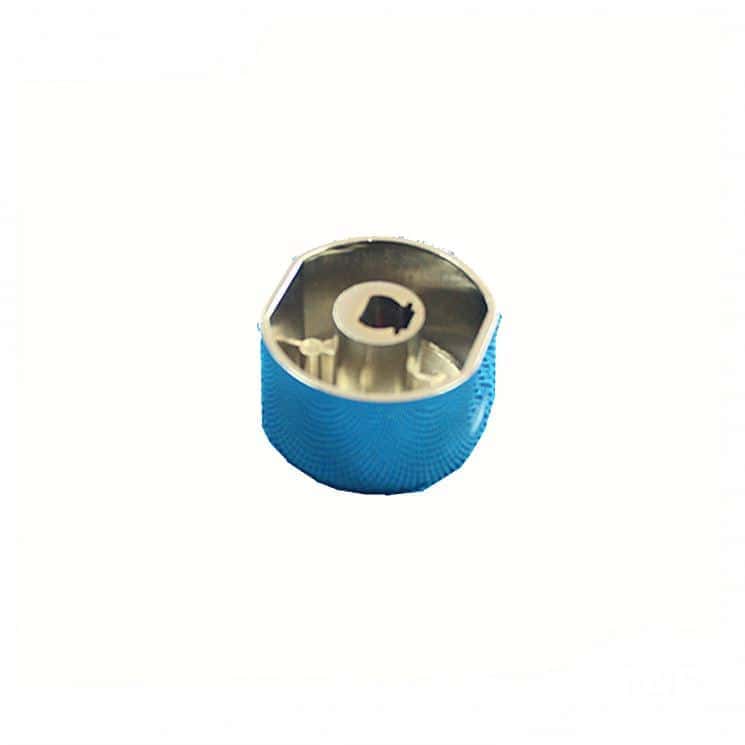

Exquisite finishing treatments

Moldie also offer a wide selection of aesthetic finishes for your customized die cast knob—including sandblasting, anodizing, and powder coating—all customizable to match your desired appearance and functional needs.

We understand that each project has unique requirements, which is why we provide tailored finishing options to enhance both the look and durability of your components. Our expert team works closely with you to ensure the chosen finish not only meets your specifications but also improves the overall performance of the part. Each part is produced using high-pressure die casting for complex geometries and high dimensional accuracy, allowing for consistent quality and precision across all orders.

Our quality management system is ISO 9001:2015 certified, guaranteeing that every component meets rigorous international standards. This certification reflects our ongoing commitment to excellence and continuous improvement in all aspects of our manufacturing processes. We regularly conduct thorough inspections and quality control measures to ensure that every die cast knob leaving our facility exceeds customer expectations.

We are dedicated to providing exceptional service and expert guidance throughout the entire production process to help bring your designs to life efficiently and effectively. Partner with a trusted die casting parts manufacturer—contact us today to discuss your project requirements!

Trade information

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port |