Mold flow analysis is a simulation technique used in plastic injection molding to predict how molten plastic will move through a mold. By running these tests on a computer, manufacturers can adjust key elements such as gate location, wall thickness, and material choice, reducing costly mistakes and saving valuable time.

For anyone involved in designing or producing injection-molded parts, understanding mold flow analysis leads to better decisions, fewer surprises, and faster paths to production.

Core Principles of Mold Flow Analysis

Mold Flow Analysis allows engineers to see how molten plastic will behave inside a mold during injection molding. By understanding flow patterns, filling behavior, and key variables like pressure and temperature, manufacturers can improve product quality and avoid costly tool changes.

Simulation of Molten Plastic Flow

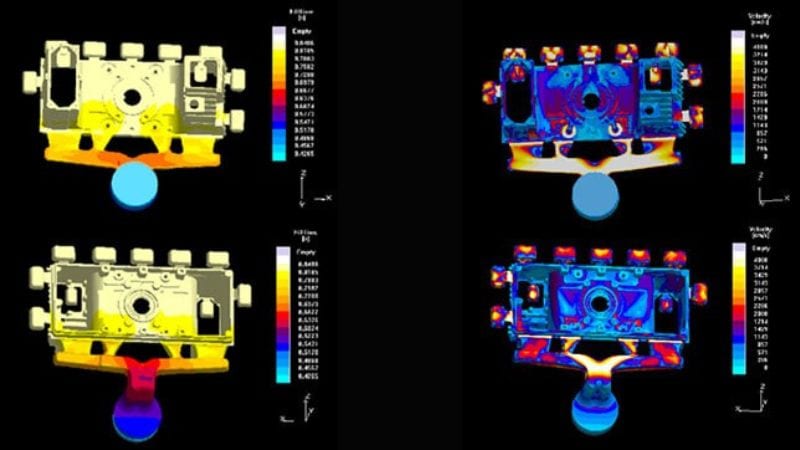

Mold Flow Analysis uses computer-aided engineering (CAE) tools to create a virtual simulation of the injection molding process. The software takes a 3D part model and predicts how molten plastic will fill every part of the mold cavity.

During simulation, the path and speed of the plastic flow are shown in detail. This helps detect regions where the resin might move too slowly, get stuck, or fail to fully fill.

Engineers can also test different injection points or gate locations before committing to a mold design. By visualizing the movement of plastic, they adjust part features early to prevent problems like air traps or incomplete sections.

Predicting Filling Behavior

Filling behavior is one of the most critical outputs of Mold Flow Analysis. The software predicts whether the molten plastic will reach all areas of the mold smoothly and evenly.

Potential issues like weld lines, hesitation marks, or air traps are highlighted on the part model. Weld lines appear where different flow fronts meet, which can cause weak spots in the product.

With this information, engineers can change wall thickness, modify the layout, or select better gate locations to improve filling. They rely on these predictions to avoid defects, reduce waste, and ensure the finished product closely matches its intended design.

Pressure and Temperature Distribution

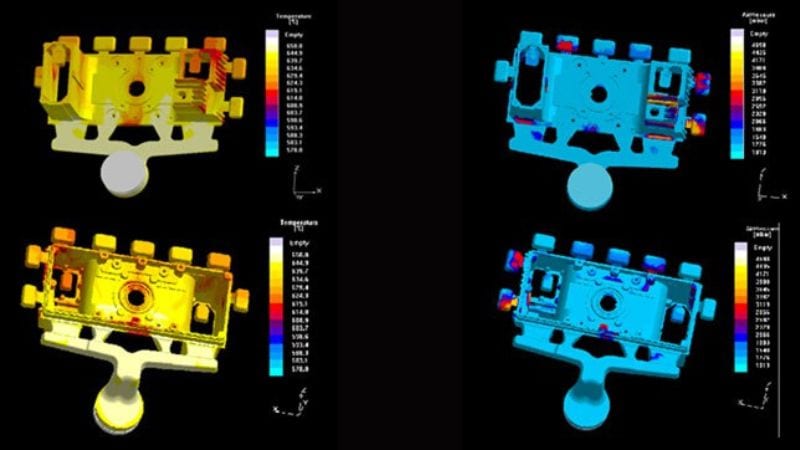

Mold Flow Analysis also simulates pressure and temperature across the mold during filling and cooling. It tracks how much injection pressure is needed at different points and how heat moves through the mold walls and the plastic itself.

This data is used to find areas of high pressure, which can cause flash, sink marks, or even damage to the mold. Temperature maps show where the plastic may cool too quickly or too slowly, leading to warping or shrinkage.

By understanding these pressures and temperature gradients, manufacturers can optimize the cooling system, improve cycle time, and lower the risk of defects. The end result is a more predictable, efficient, and cost-effective injection molding process.

Optimizing Mold and Part Design

Mold flow analysis helps engineers detect and prevent common defects before expensive tooling begins. This process improves overall part quality by focusing on crucial elements like mold layout, part shape, material use, and how plastic enters and moves inside the mold.

Mold Design and Cavity Configuration

Efficient mold design begins with careful cavity configuration. The number and arrangement of cavities influence production output, but also impact filling balance and cooling rates.

A well-designed cavity reduces variations between parts. Mold flow analysis predicts how molten thermoplastic, such as PC or ABS, moves through each cavity. This lets designers correct early for issues like uneven packing or temperature differences.

Key design features include parting lines position, ejection locations, and cooling channel layout. Simulations show where redesigns are needed to minimize warping or sink marks. Optimizing the mold layout leads to better part consistency and faster cycle times.

Part Geometry and Wall Thickness

Part geometry, especially wall thickness, plays a major role in mold filling and cooling. Thick sections cool slower than thin ones, which can cause warping, shrinkage, or sink marks.

Mold flow analysis pinpoints areas where wall thickness should be adjusted for better filling or reduced stress. Using a uniform wall thickness wherever possible prevents defects and improves strength.

Sharp corners, deep ribs, or sudden transitions in wall size are highlighted by simulation for redesign. Modifying these features supports better resin flow and reduces production rejects. Simple shapes with consistent thickness keep molding stable and efficient.

Gate Placement and Venting Solutions

Gate placement controls how melted material enters the cavity. Poor gate location or size can cause short shots, air traps, or uneven filling.

Simulation tools recommend gate positions that allow smooth, balanced flow without high pressure. Side, edge, or pin gates are tested virtually before physical molds are made. Correct gate sizing also avoids jetting or weld lines that impact part appearance.

Venting is critical for air escape. Mold flow analysis finds areas likely to trap air, then suggests vent placement to release it. Proper venting saves time by reducing the need for tool rework and helps maintain surface quality in cosmetic parts.

Material Selection and Properties

The choice of resin has a big influence on the injection molding process. Different materials like ABS or PC have unique flow and cooling behaviors.

Mold flow analysis compares how thermoplastics fill molds, revealing trouble spots before production starts. Properties like melt temperature, viscosity, and shrinkage rates are examined to ensure the material matches both design and function needs.

Simulations help manufacturers test several materials virtually, reducing mistakes and wasted material. By choosing the right resin and understanding its flow characteristics, engineers lower defect rates and improve the lifespan of both part and mold.

Implementing Mold Flow Analysis in Manufacturing

Using Mold Flow Analysis (MFA) improves part quality, reduces defects, and lowers manufacturing costs. With the right approach and tools, MFA helps teams make better decisions about product design and the tooling process.

Integrating MFA in DFM and Tooling Processes

Incorporating MFA while working on Design for Manufacturability (DFM) allows engineers to predict fill patterns, detect possible trouble spots, and minimize overpacking. Early simulation supports good decisions about gate locations and wall thickness before cutting steel.

Collaboration between design teams and tooling engineers is essential. Sharing simulation findings leads to practical changes in mold design—such as adjusting draft angles, vent placement, or cooling channel placement. This upfront effort helps lower the risk of problems like warpage or voids during later mold trials.

Simulation Software and Analysis Workflow

Software like Moldflow and Moldex3D allow detailed injection molding simulations. Users import part geometry, select material data including thermal conductivity and viscosity, and set up process conditions such as temperature and pressure.

A typical workflow starts by simulating plastic flow. Engineers analyze areas prone to pressure drop, short shots, or weld lines. Then, the cooling phase is simulated to estimate cooling time, temperature gradients, and possible hot spots.

Reducing Lead Time and Cycle Time

MFA allows manufacturing teams to simulate multiple design alternatives without physical trials. By identifying and fixing issues early, they reduce the number of required mold iterations.

Fast analysis of cooling layouts helps shorten cooling time, which is often the largest part of the cycle time. Understanding thermal conductivity and optimizing coolant paths leads to more uniform cooling and less warping.

By resolving issues in the virtual stage, teams can cut lead time for new tools. Production can also start sooner with fewer interruptions for tool adjustments or unexpected defects.

Frequently Asked Questions

How does mold flow analysis software integrate with CAD programs like SolidWorks or ANSYS?

Many mold flow analysis programs allow direct import of CAD files from SolidWorks and ANSYS. Some use plug-ins or built-in add-ins so engineers can run simulations within their CAD environment.

This integration means design changes in the CAD model quickly update in the analysis software. As a result, it helps save time and reduces errors during the design and simulation process.

What features distinguish the best mold flow analysis software in the industry?

Leading software usually includes advanced simulation tools like flow front tracking, cooling analysis, and warp prediction. They support a wide range of plastic materials and provide detailed result visualization, such as pressure maps and temperature graphs.

Other helpful features include automatic mesh generation, support for multi-cavity molds, and easy report creation. Some programs also connect with company databases for material and project management.

Are there viable free alternatives to commercial mold flow analysis software for small-scale projects?

Some free or open-source programs offer basic mold flow simulations. These tools can be useful for students or small projects that do not need detailed results. However, free software often lacks advanced analysis features, user support, and frequent updates.

Users working on complex parts or requiring high accuracy may find commercial software more suitable. For simple tasks or learning purposes, free options may be enough.