Cold chamber die casting plays a key role in modern manufacturing by shaping strong, precise parts from metals with high melting points. It is a process where molten metal is injected under high pressure into a mold to create complex and durable components. This method is widely used in industries that demand accuracy, efficiency, and reliable performance.

By exploring how the manufacturing process works, what materials it uses, and where it is applied, it becomes clear why manufacturers rely on cold chamber die casting for parts that must meet demanding standards. The following sections will explain the process in detail, compare it to hot chamber die casting, and highlight its applications.

What Is Cold Chamber Die Casting?

Cold chamber die casting is a metal casting process used when working with alloys that have high melting points, such as aluminum, copper, and magnesium. It relies on a separate melting furnace and an external injection system to form precise, durable parts under high pressure.

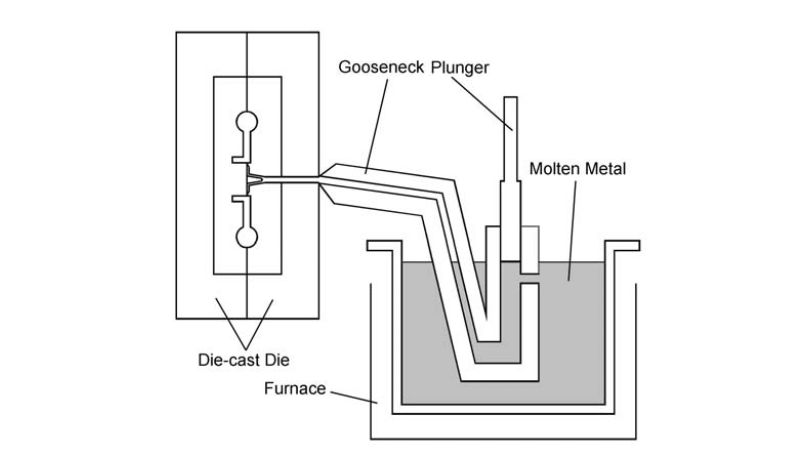

Cold chamber die casting is a method where molten metal is transferred from a furnace into a separate injection chamber. A plunger then forces the molten metal into a steel die under high pressure.

This process differs from hot chamber die casting because the injection system is not submerged in molten metal. By keeping the melting furnace and injection system separate, manufacturers can use metals that would otherwise corrode or wear down hot chamber equipment. This makes cold chamber die casting the preferred choice for aluminum and copper-based alloys.

It is widely used in industries that require strong, lightweight, and complex parts. Automotive engine housings, aerospace components, and electronic casings are common examples. The process is valued for producing consistent parts with smooth surfaces and accurate dimensions.

Cold Chamber Die Casting Process Steps

Cold chamber die casting relies on a sequence of controlled steps that ensure accurate part formation. Each stage, from preparing the mold to ejecting the solidified piece, affects the final quality, strength, and precision of the casting.

Mold Preparation

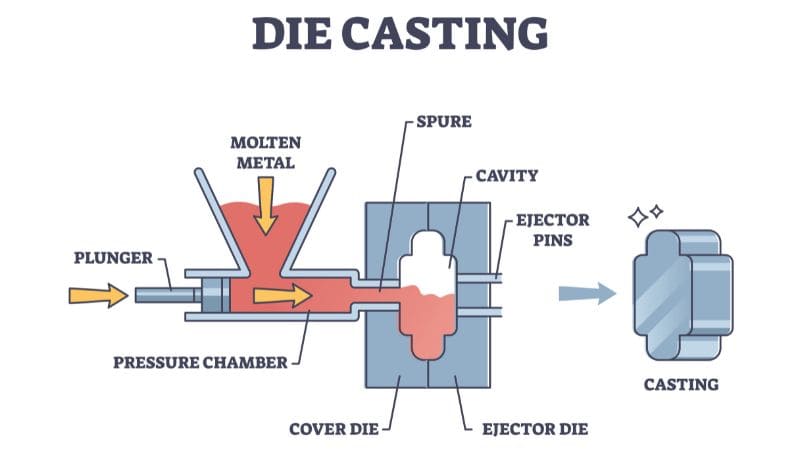

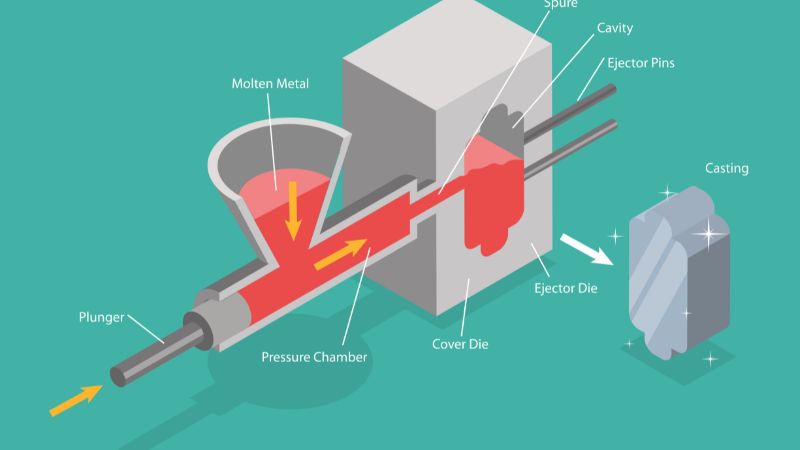

The process begins with preparing the die, which consists of two halves that form the mold cavity. These halves must be cleaned and coated with a release agent to prevent sticking and reduce wear.

Proper mold temperature is important. Heating the die before casting helps reduce defects such as cold shuts or incomplete filling. It also improves metal flow inside the cavity.

Clamping the die halves together with high force ensures no metal escapes during injection. The clamping system must hold the mold tightly to withstand the pressure created by the plunger.

Metal Melting and Transfer

In cold chamber die casting, metals with high melting points such as aluminum, brass, and copper are commonly used. The metal is first melted in a separate furnace away from the casting machine. Once molten, the metal is carefully ladled or poured into the injection chamber.

The amount of molten metal transferred must match the cavity size. Too much metal can cause flash, while too little may result in incomplete filling. Careful measurement ensures consistency from cycle to cycle.

Injection and Filling

The plunger plays a central role in this stage. After the molten metal enters the injection chamber, the plunger pushes it forward under high pressure.

The injection pressure must be strong enough to force the metal into every part of the mold cavity, including thin walls and fine details. The speed and force of the plunger are controlled to avoid turbulence that could trap air or cause porosity.

The injection chamber and gating system guide the molten metal into the mold cavity. Proper design of these pathways ensures smooth flow and reduces the risk of defects.

This stage ends once the cavity is fully filled and the metal begins to solidify under pressure.

Cooling, Ejection, and Finishing

After the cavity fills, the molten metal cools and solidifies inside the mold. Cooling time depends on the part’s thickness, size, and chosen alloy. Maintaining pressure during cooling helps reduce shrinkage and improves dimensional accuracy.

Once solidified, the die halves open, and ejector pins push the casting out of the mold. The ejection system must release the part without damaging its surface or shape.

Post-processing steps follow ejection. These may include trimming excess material, removing flash, or machining surfaces for tighter tolerances. Some castings also undergo heat treatment or surface finishing to meet specific requirements.

By the end of this stage, the casting is ready for inspection and further use in production.

Materials Used in Cold Chamber Die Casting

Cold chamber die casting relies on metals that can withstand high temperatures and maintain strength under demanding conditions. These materials are chosen for their melting points, durability, corrosion resistance, and ability to produce precise, long-lasting parts.

High-Melting-Point Metals

Cold chamber machines are designed for non-ferrous metals with higher melting points than hot chamber systems. Examples include aluminum alloys, copper alloys, magnesium, and certain zinc alloys with high aluminum content.

Key advantages of high-melting-point metals in die casting:

- Better strength and hardness compared to low-melting-point metals

- Resistance to wear and deformation at elevated temperatures

- Suitability for structural and load-bearing parts

Industries such as automotive, aerospace, and industrial equipment often rely on these materials because they balance strength with precision. Their ability to produce complex shapes with consistent quality makes them essential for demanding applications.

Aluminum Alloys

Aluminum die casting is the most common use of cold chamber machines. Aluminum alloys combine lightweight properties with good mechanical strength and excellent corrosion resistance. These traits make them ideal for producing housings, brackets, and engine components.

Aluminum also has high thermal and electrical conductivity, which benefits parts used in electronics and heat management systems. Unlike some other metals, aluminum maintains its performance across a wide temperature range, making it reliable in both indoor and outdoor environments.

Manufacturers often choose aluminum die castings for high-volume production because the alloy flows well into detailed molds. This results in parts with smooth surfaces and dimensional accuracy, reducing the need for secondary machining.

Common applications include:

- Automotive components such as transmission cases and engine blocks

- Consumer electronics housings

- Industrial machinery parts requiring lightweight strength

Magnesium and Copper Alloys

Magnesium alloys are valued for being the lightest structural metals available. They offer good strength-to-weight ratios, making them useful in aerospace and automotive parts where weight reduction is critical. Magnesium also provides excellent machinability and good thermal conductivity, though it requires careful handling due to its reactivity.

Copper alloys, on the other hand, stand out for their high tensile strength, wear resistance, and superior conductivity. These properties make copper alloys suitable for electrical components, plumbing fixtures, and parts exposed to heavy loads.

While copper is heavier than aluminum or magnesium, it offers durability in applications that demand long service life and resistance to corrosion. Its ability to withstand extreme operating conditions makes it a strong choice for industrial and high-performance parts.

Together, magnesium and copper alloys expand the range of cold chamber die casting by providing options that balance weight, strength, and conductivity for specialized needs.

Cold Chamber vs. Hot Chamber Die Casting

Cold chamber and hot chamber die casting both use pressure to force molten metal into a die, but they differ in how the metal enters the machine and which alloys they can handle. These differences affect cycle time, tool life, and the types of parts that can be produced.

Fundamental Differences

In cold chamber die casting, molten metal is poured into a separate shot sleeve and then injected into the die. This process is slower because it requires manual or automated ladling. It is used for metals with high melting points, such as aluminum, brass, and certain magnesium alloys.

In hot chamber die casting, the injection system is submerged in a furnace of molten metal. The machine pumps the metal directly into the die, which makes the process faster and more efficient. This method is ideal for metals with lower melting point like zinc, lead, and some magnesium alloys.

A key difference lies in equipment wear. Hot chamber machines experience less stress because they use softer alloys, while cold chamber machines must withstand higher temperatures that can shorten tool life.

| Feature | Cold Chamber | Hot Chamber |

|---|---|---|

| Metal type | Aluminum, brass, magnesium (high melting) | Zinc, lead, magnesium (low melting) |

| Cycle speed | Slower | Faster |

| Metal handling | Ladled into shot sleeve | Pumped directly from furnace |

| Tool wear | Higher | Lower |

Applications of Cold Chamber Die Casting

Cold chamber die casting supports industries that need precise, durable, and lightweight metal parts. It is especially valuable for components made from aluminum and other alloys that require high strength and accurate dimensions.

Automotive Components

Automakers use cold chamber die casting to create engine blocks, cylinder heads, and transmission housings. These parts must handle heat, pressure, and mechanical stress, making aluminum die castings a common choice. The process ensures tight tolerances and consistent quality, which reduces the need for secondary machining.

Lightweight suspension parts, such as control arms and steering knuckles, are also produced through this method. By reducing part weight without sacrificing strength, manufacturers improve fuel efficiency and vehicle handling.

The ability to form complex shapes with thin walls allows engineers to design parts that balance performance with cost savings. This makes cold chamber die casting a standard process in modern automotive manufacturing.

Industrial and Electrical Parts

In industrial equipment, die cast housings and brackets benefit from the strength and durability of cold chamber methods. Components can be produced with smooth surfaces and precise dimensions, reducing assembly issues and improving reliability.

Electrical connectors, enclosures, and motor housings require both accuracy and resistance to wear. Cold chamber die casting allows the use of alloys like aluminum and copper, which provide good conductivity and corrosion resistance.

The process also supports high-volume production of parts with consistent quality. This is critical for sectors such as power distribution, heavy machinery, and renewable energy equipment, where long service life and safety are priorities.

Consumer Goods and Electronics

Cold chamber die casting is widely used in consumer goods where both appearance and durability matter. Items like kitchen appliances, power tool housings, and furniture hardware often rely on aluminum die castings for strength and a clean finish.

In electronics, manufacturers use the process for mobile phone casings, laptop hinges, and audio equipment enclosures. These parts need to be lightweight yet strong enough to protect sensitive components.

The smooth surfaces and fine details achievable with die casting also reduce finishing steps, which lowers costs while maintaining a high-quality appearance. This balance of function and design makes the process valuable in consumer markets.

Frequently Asked Questions

What are the primary advantages of using cold chamber die casting?

This process produces parts with high dimensional accuracy and smooth surface finishes. It can form thin walls and complex shapes that would be difficult with other manufacturing methods.

It also supports large production runs with consistent quality, making it efficient for industries that need high-volume parts.

In what applications is cold chamber die casting most commonly used?

Automotive manufacturers use it for engine blocks, transmission housings, and structural parts. Aerospace companies rely on it for lightweight but strong components.

It is also used in electronics for housings and in medical equipment where precision and durability are required.

What are the limitations of cold chamber die casting?

The equipment has higher setup costs because it requires a separate furnace. The process can also be slower than hot chamber casting due to the extra step of transferring molten metal.

It is not ideal for very large parts or for metals with low melting points, which are better suited to hot chamber casting.