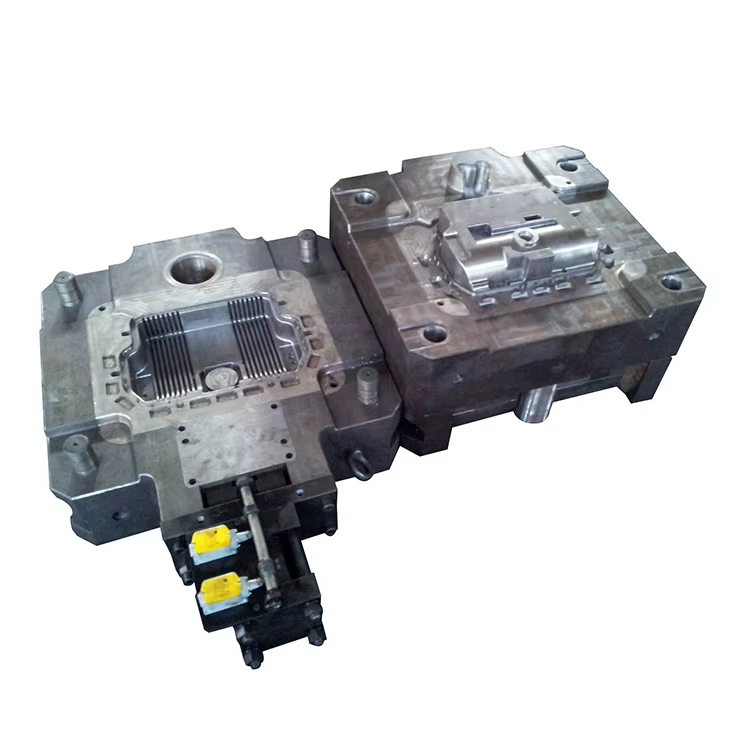

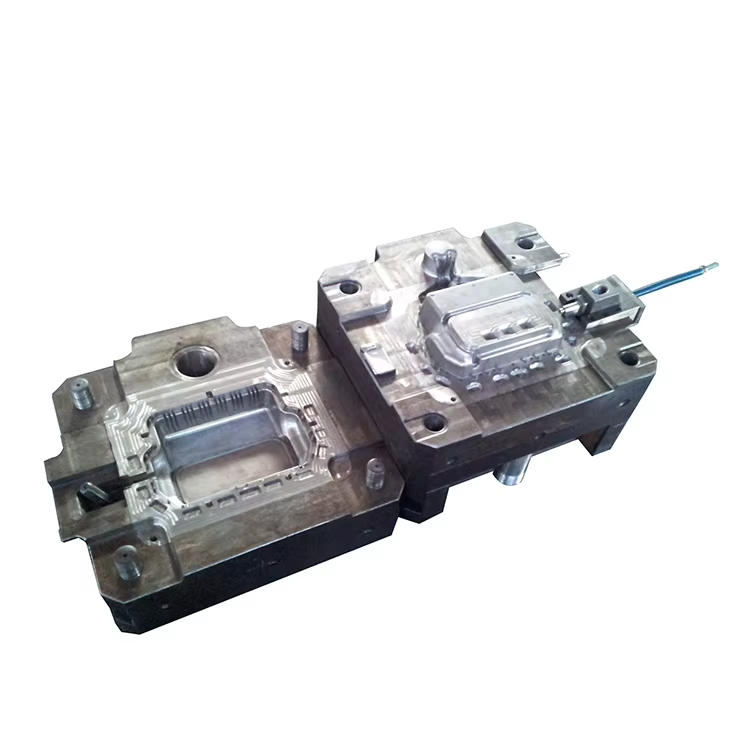

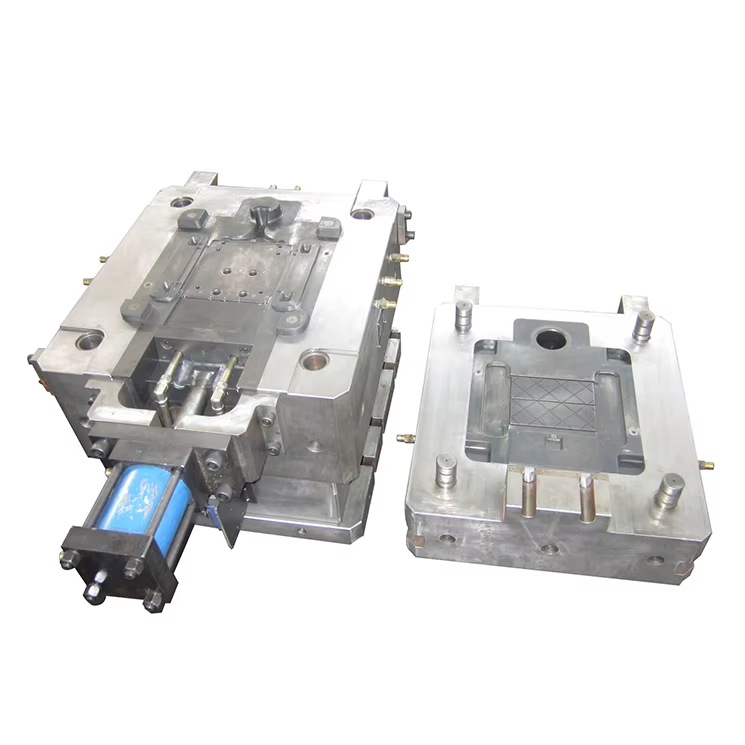

Discover premium-quality China aluminum alloy die casting mold solutions, expertly designed to meet your manufacturing needs. As a leading name in the industry, Moldie integrates artistry and precision engineering into every mold we create.

Our molds are crafted using robust materials like ADC12 and AlSi9Cu3, ensuring reliable performance and unmatched durability. The mold base, featuring LKM C50 + P20 and fortified with materials such as cast iron, includes high-quality inserts like Dievar and 1.2344 tool steel to cater to your specific requirements.

We adhere to internationally recognized standards like HASCO and DME while delivering finishes that range from sandblasting for a rustic appeal to anodizing for a polished look—all fully customizable to the shape and color you desire.

Our commitment to quality is backed by ISO 9001:2015 certification, guaranteeing superior craftsmanship and long-term reliability. Additionally, all molds undergo heat treatment exceeding >HRC45, ensuring exceptional strength for demanding applications.

Key Features

– Mold materials: ADC12, AlSi9Cu3, and more.

– High-quality base: LKM C50 + P20 with premium inserts (Dievar, 1.2344).

– Compliance with global standards: HASCO, DME.

– Finishes: Sandblasting, anodizing, and customizable options.

– Heat treatment: Hardness >HRC45 for durability.

Trade information

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port |

Some pictures of our die casting parts: