What are die-casting and Surface Finishes?

Die casting is a popular method to create detailed and precise metal parts, commonly used across industries.

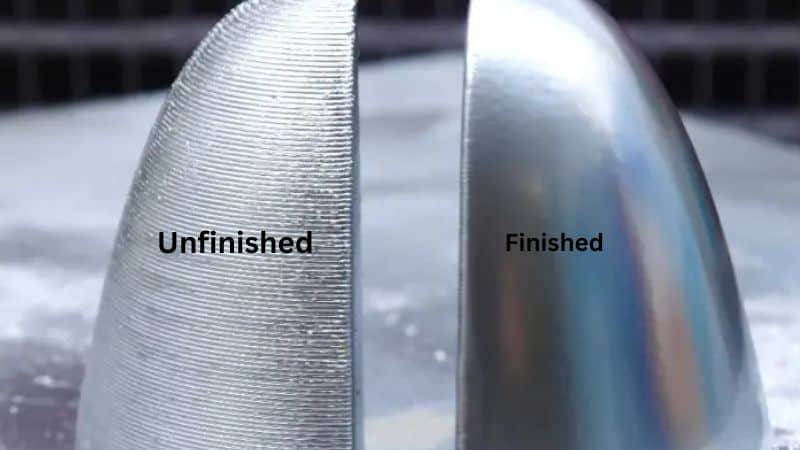

After die casting, surface finishes come into play. The surface finish is like a final touch that improves the quality and appearance of the metal. This process can give you a product that looks good and lasts longer.

When it comes to surface finishing, you have several options. You can add texture or polish to make the surface shiny. Each choice will affect the final look, durability, and performance of your die-cast parts. Some of these finishes also provide additional benefits, like improved corrosion resistance.

Why are Surface Finishes Critical?

- Aesthetics: A good finish means a more appealing product.

- Functionality: The right finish can enhance performance.

- Protection: Finishes often defend against wear and tear.

Common Surface Finishing Option in Die Casting

Mechanical Finishing

Mechanical finishing encompasses physical methods that alter the surface topography of die cast parts without changing their chemical composition. These processes primarily aim to improve surface smoothness and dimensional accuracy and prepare the surface for subsequent treatments.

Grinding

Grinding involves the use of abrasive wheels or belts to remove excess material from the die cast surface. This process achieves high precision and smoothness, making it ideal for components requiring tight tolerances and enhanced surface quality.

- Advantages:

- High dimensional accuracy.

- Smooth surface finish.

- Effective removal of surface irregularities.

- Disadvantages:

- High energy consumption.

- Potential for introducing micro-cracks if not properly controlled.

Polishing

Polishing employs abrasive materials to achieve a high-gloss, reflective surface finish. It is commonly used for aesthetic purposes or where reduced friction is desired.

- Advantages:

- Enhanced visual appeal with a shiny finish.

- Improved surface lubricity.

- Removal of minor surface defects.

- Disadvantages:

- Time-consuming process.

- Not suitable for all types of die cast materials.

Deburring

Deburring removes sharp edges and burrs resulting from the die casting process. It ensures safety, improves part functionality, and prepares the surface for further finishing.

- Advantages:

- Increased safety by eliminating sharp edges.

- Enhanced fit and assembly of parts.

- Prevention of corrosion by removing trapped debris.

- Disadvantages:

- Additional processing step increases production time.

- Requires skilled operators to ensure consistency.

Shot Blasting

Shot blasting uses a stream of abrasive particles propelled at high speed to clean and smooth die cast surfaces. It also imparts a uniform texture, which can enhance the adhesion of subsequent coatings.

- Advantages:

- Effective cleaning and surface preparation.

- Uniform surface texture for better coating adhesion.

- Removes surface contaminants and oxidation.

- Disadvantages:

- Can introduce surface stress if not properly controlled.

- Requires specialized equipment and safety measures.

Chemical Finishing

Chemical finishing involves altering the surface properties of die castings through chemical reactions. These processes are essential for enhancing corrosion resistance, improving adhesion properties, and preparing surfaces for further treatments.

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum die cast surfaces, enhancing corrosion resistance and surface hardness. It also allows for dyeing, providing a wide range of color options.

- Advantages:

- Increased corrosion and wear resistance.

- Enhanced surface hardness.

- Ability to incorporate decorative colors.

- Disadvantages:

- Limited to specific thicknesses.

- Requires precise control of process parameters.

Chemical Conversion Coatings (CCC)

CCC processes involve immersing die cast parts in chemical baths to form a protective layer. Common types include chromate and phosphate coatings, which improve corrosion resistance and paint adhesion.

- Advantages:

- Enhanced corrosion protection.

- Improved adhesion for paints and other coatings.

- Cost-effective compared to some other methods.

- Disadvantages:

- Environmental concerns, particularly with chromate-based coatings.

- Limited aesthetic enhancement.

Passivation

Passivation is a chemical treatment that removes free iron and other contaminants from the surface, enhancing corrosion resistance. It is commonly used for stainless steel die cast parts.

- Advantages:

- Improved corrosion resistance.

- Minimal impact on dimensional tolerances.

- Environmentally friendly options available.

- Disadvantages:

- Limited to materials that form a protective oxide layer.

- Requires proper handling of chemicals.

Thermal Finishing

Thermal finishing involves applying heat to alter the microstructure and surface characteristics of die-cast parts. These treatments enhance mechanical properties, stress distribution, and surface integrity.

Heat Treatment

Heat treatment processes such as annealing, quenching, and tempering are used to relieve internal stresses, increase ductility, and improve mechanical strength.

- Advantages:

- Enhanced mechanical properties.

- Improved dimensional stability.

- Relief of residual stresses from the die casting process.

- Disadvantages:

- Requires precise temperature control.

- Potential for surface oxidation if not properly managed.

Tempering

Tempering involves reheating die cast parts to a specific temperature and then cooling them to achieve desired mechanical properties without compromising surface integrity.

- Advantages:

- Balances hardness and toughness.

- Reduces brittleness.

- Enhances overall durability.

- Disadvantages:

- Additional processing step increases production time.

- Requires careful monitoring to prevent over-tempering.

Coatings and Paints

Applying coatings and paints is a prevalent method to achieve both aesthetic and functional improvements on die castings. These surface treatments provide color, protection, and specialized properties tailored to specific applications.

Powder Coating

Powder coating involves applying a dry, powdered paint to the die cast surface, which is then cured under heat to form a durable finish. It offers excellent protection against corrosion, chipping, and fading.

- Advantages:

- Wide range of color and finish options.

- Superior durability and resistance to environmental factors.

- Minimal waste compared to liquid paints.

- Disadvantages:

- Requires specialized equipment for application and curing.

- Limited to conductive surfaces or those that can be made conductive.

Liquid Painting

Liquid painting involves spraying or dipping die cast parts in liquid paint, followed by drying or curing. It provides high-quality, versatile finishes suitable for various environments.

- Advantages:

- High level of detail and color depth.

- Flexibility in application techniques.

- Can be applied to non-conductive surfaces.

- Disadvantages:

- Higher environmental impact due to solvent emissions.

- Possibility of runs, drips, or uneven coverage if not properly applied.

Electrocoating (E-Coating)

E-coating is an electrochemical process where die cast parts are submerged in a tank containing paint particles and an electrical current is applied. The paint is uniformly deposited onto the surface, ensuring complete coverage, including complex geometries.

- Advantages:

- Uniform and consistent coating.

- Excellent corrosion protection.

- Efficient for high-volume production.

- Disadvantages:

- Limited color options compared to other painting methods.

- Requires careful control of process parameters.

Electroplating

Electroplating involves depositing a thin layer of metal onto the die cast surface through an electrochemical process. This technique enhances surface properties such as conductivity, corrosion resistance, and aesthetic appeal.

Zinc Plating

Zinc plating provides sacrificial protection against corrosion, making it ideal for outdoor or harsh environment applications. It also improves surface hardness and wear resistance.

- Advantages:

- Effective corrosion protection.

- Cost-effective compared to some other plating options.

- Enhances surface durability.

- Disadvantages:

- Limited aesthetic appeal.

- Zinc can be brittle if applied too thickly.

Nickel Plating

Nickel plating offers superior corrosion resistance and creates a smooth, lustrous finish. It is commonly used in applications requiring high durability and aesthetic quality.

- Advantages:

- Excellent corrosion and wear resistance.

- Attractive metallic finish.

- High hardness and durability.

- Disadvantages:

- Higher cost compared to zinc plating.

- Requires precise control to avoid surface defects.

Chromium Plating

Chromium plating provides a mirror-like finish with exceptional hardness and resistance to tarnishing. It is often used for decorative purposes as well as to enhance wear resistance.

- Advantages:

- Superior hardness and durability.

- Highly reflective and aesthetically pleasing.

- Excellent corrosion resistance.

- Disadvantages:

- Expensive compared to other plating options.

- Environmental and health concerns due to hazardous chemicals used in the process.

What are the Surface Finishing Grades

Die-casting surface finishes are systematically categorized into several grades, each addressing specific needs based on the intended application and desired properties of the final product.

Utility Grade is the most basic level, providing fundamental protection against corrosion and wear. This grade is typically applied to internal components or parts not visible in the final assembly, where the primary concern is functionality rather than appearance.

Commercial Grade strikes a balance between aesthetics and functionality, offering a moderate level of surface protection while maintaining a presentable appearance. This grade is ideal for products intended for commercial markets where both cost-effectiveness and visual appeal are important.

Consumer Grade focuses more on enhancing the visual attractiveness of the product. It often includes decorative finishes that improve the overall look, making it especially suitable for consumer electronics and household appliances where the appearance is as critical as performance.

At the pinnacle is Superior Grade, which epitomizes the highest standards of surface finishing. This grade is reserved for industries demanding exceptional durability, tensile strength, and precise material composition, such as the automotive and aerospace sectors.

Superior Grade finishes ensure that components can withstand extreme conditions and stresses without compromising their structural integrity.

Different Finishing Classes with Specific Standards

Beyond grading, die casting surface finishes are further classified into distinct classes, each adhering to specific standards that cater to different application needs:

- Finish Class 1: Characterized by a high-gloss surface, this class is perfect for decorative or consumer-facing applications where a shiny and attractive appearance is desired. It is commonly used in products where the surface finish contributes significantly to the product’s market appeal.

- Finish Class 2: Offering a matte or semi-gloss finish, this class provides versatility for both visible and internal components. The subdued sheen helps reduce glare and can also hide minor surface imperfections, making it suitable for a wide range of applications where both aesthetics and practicality are important.

- Finish Class 3: This class involves specialized coatings or treatments aimed at enhancing specific properties such as electrical conductivity or wear resistance. It is typically employed in industrial machinery and equipment where improved performance metrics like enhanced durability or better heat dissipation are required.

Specific Industry Standards for Surface Finish in Die Casting?

There are industry standards for die casting surface finishes that ensure part consistency and quality. Standards such as those from the American Society for Testing and Materials (ASTM) offer guidelines for acceptable surface finish levels. These standards help you make sure that your parts meet the expected performance and aesthetic requirements for their intended use.

Key Standards Include:

- ISO 1302:Specifies the standards for surface roughness and texture.

- ASTM B633:Covers the specifications for anodic oxidation of aluminum.

- SAE Standards:Define requirements for automotive-grade finishes, ensuring performance under vehicle operating conditions.

Working with Moldie Casting

Choosing the right partner for your die casting needs is crucial. Moldie Casting stands out as a premier choice in the industry, offering a blend of expertise, quality, and customer-centric services that ensure your projects are executed from start to finish.

Whether you are embarking on a new project or seeking to enhance your existing manufacturing processes, Moldie Casting provides the quality, reliability, and support you need to achieve your objectives. Visit our website to learn more about their services.

Frequently Asked Questions

What factors contribute to the quality of die casting surface finishes?

The quality of your die cast parts’ surface finish depends on several factors such as the mold design, the type of metal used, the casting process conditions, and the level of post-processing. The mold surface’s smoothness directly influences the finish of the final product, and different materials can affect the outcome too. Careful control of the casting process, including temperature and pressure, helps prevent defects that can mar the surface.

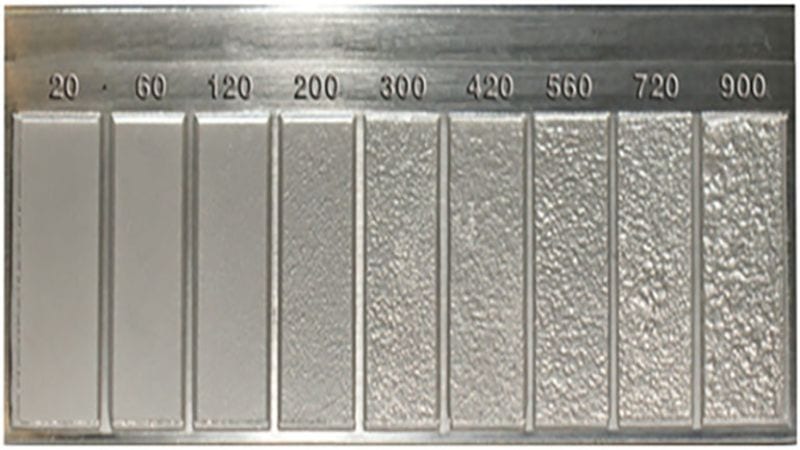

How can surface roughness be measured in die cast products?

You can measure the surface roughness of die cast products using a roughness tester, which provides readings on various roughness parameters. Common parameters include Ra, which stands for Roughness Average, and measures the average height from the lowest valley to the highest peak over a given length. This gives you a numerical value indicating the smoothness of your part’s surface.

How does high pressure die casting affect the overall surface roughness?

High pressure die casting can lead to improved surface smoothness due to the rapid filling and solidification of the molten metal under high pressure. This results in a fine-grained cast with a smoother surface compared to slower or lower pressure processes. However, it’s crucial to manage the process carefully to avoid introducing new surface defects.

Can the surface finish of die cast parts be compared to that of sand cast parts?

Yes, you can compare the surface finish of die cast parts to that of sand cast parts. Generally, die casting offers a smoother, more consistent finish than sand casting. Sand casting’s surface quality tends to be rougher due to the granularity of the sand molds. Die casting typically requires less surface finishing work than sand casting to achieve a similar level of smoothness.