Moldie offers precision-engineered custom aluminum die casting molds, ensuring high-quality results that meet your specific design and production requirements. Built on a durable LKM C50 + P20 base, these molds are designed to accommodate materials like AB steel and cast iron, with a selection of custom inserts such as Dievar and 1.2344 tailored to your exact needs.

Special features

Our molds are crafted from premium-grade aluminum alloys, including ADC12 and A360, providing exceptional toughness and durability. Enhanced with heat treatment exceeding HRC45, they deliver unparalleled resilience under high-pressure die casting processes. Achieving industry standards, our molds comply with HASCO, DME, and MISUMI benchmarks while being certified to ISO 9001:2015 – a testament to their superior quality.

To ensure visual and functional excellence, these molds can be finished to match your preferred aesthetics. Options include anodized, sandblasted, and polished surfaces, all customizable in shape and color to align with your brand identity. With lead times ranging from 3 to 10 weeks for T1 samples, our team ensures a seamless production experience, meeting your timeline and expectations.

Choose Moldie’s trusted custom aluminum die casting mold solutions for precise manufacturing, built to deliver exceptional performance. Contact us today to discuss your project and get a quote.

Trade information

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port |

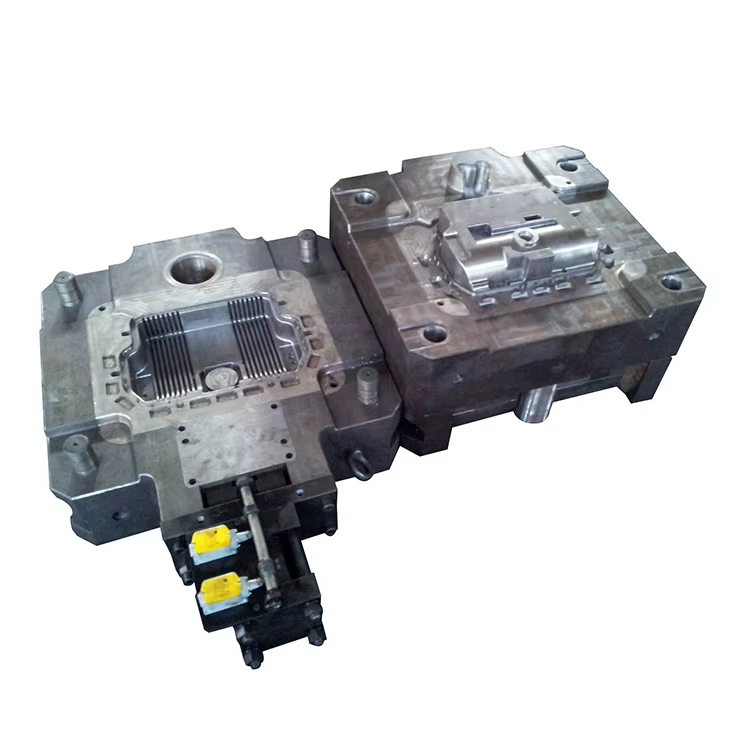

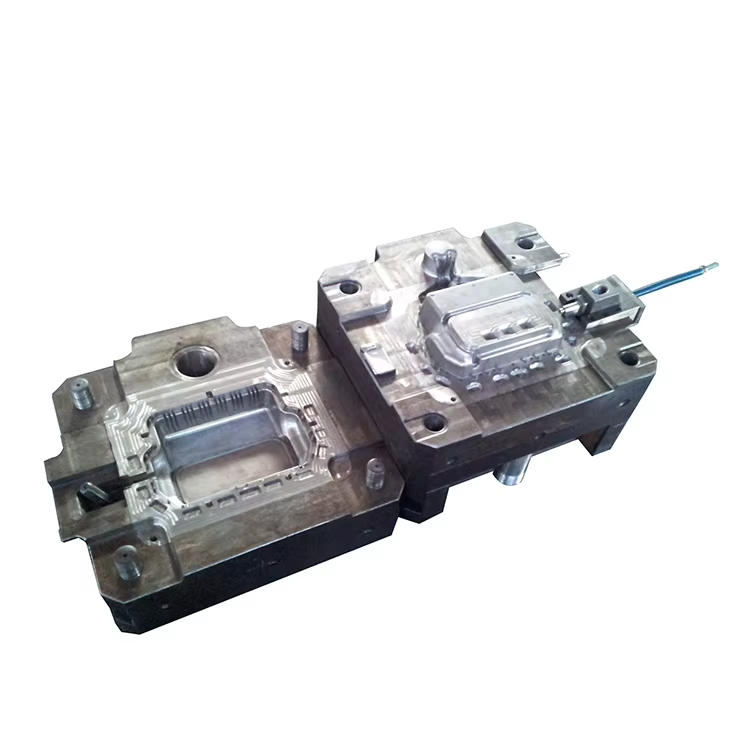

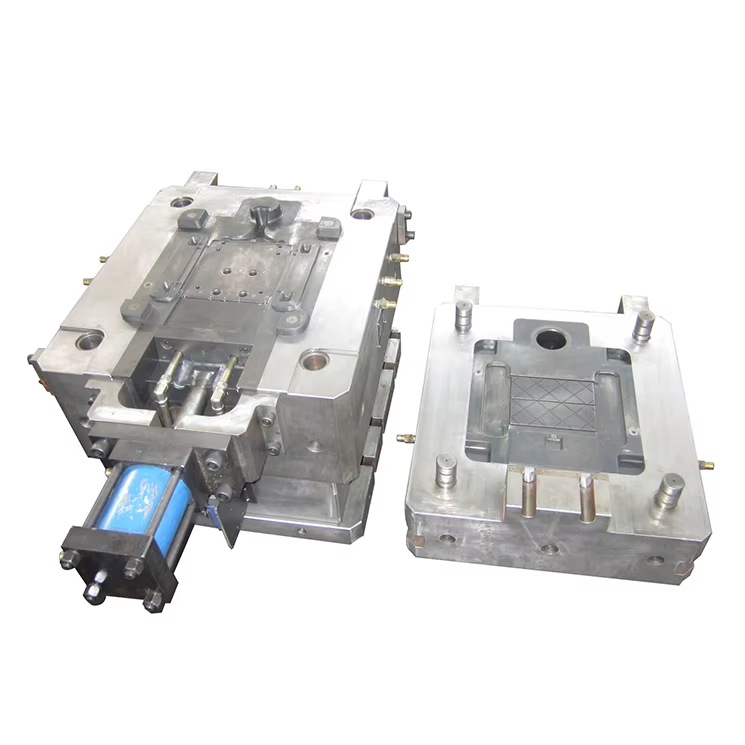

Some pictures of our die casting mold: