Moldie’s Magnesium Die Cast Brackets for Rails and Trains

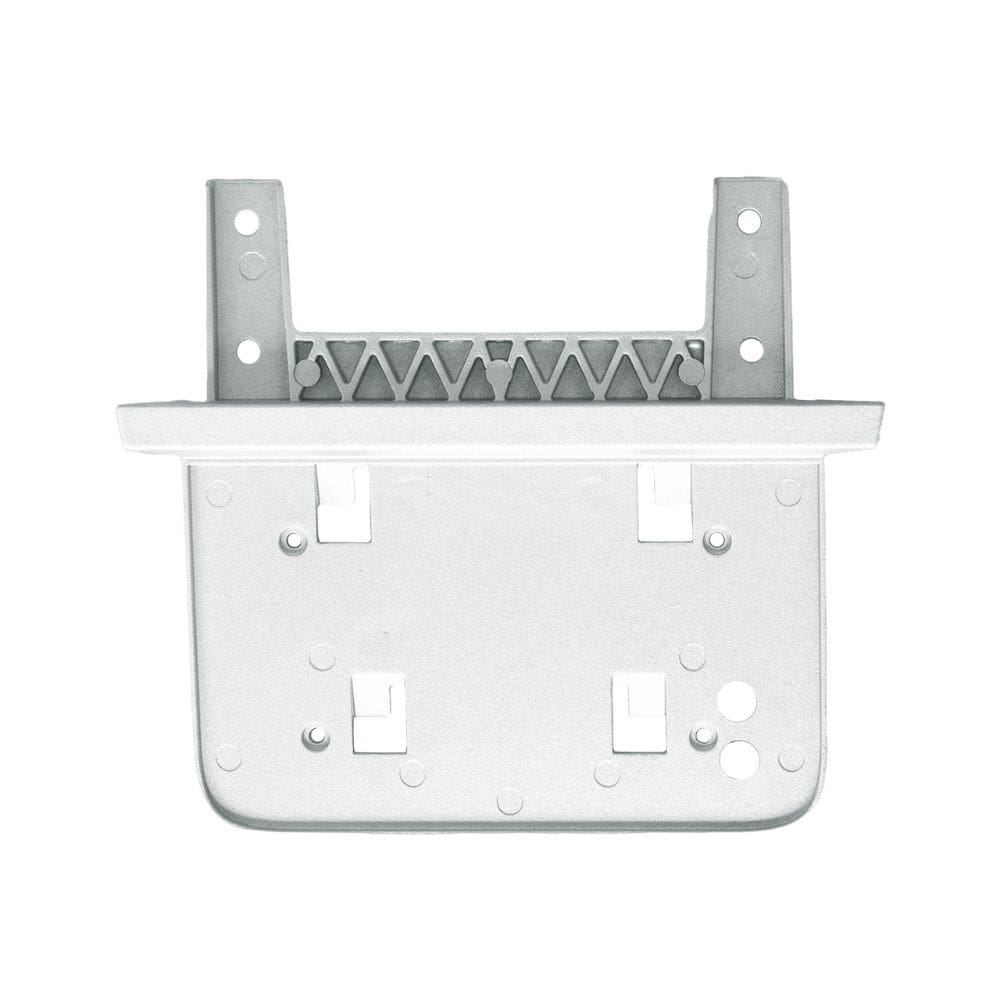

Introducing Moldie’s Magnesium Die Cast Brackets—the high-strength, lightweight mounting solution engineered to secure critical systems within modern rail vehicles.

In rail design, every component must withstand constant stress, vibration, and dynamic forces. Moldie’s brackets are manufactured using advanced magnesium die-casting technology, delivering exceptional structural integrity where it matters most. By replacing heavier, multi-part assemblies, our integrated bracket solutions reduce weight, simplify installation, and enhance overall system reliability.

Key Advantages for Structural Applications

-

High Strength-to-Weight Ratio: Magnesium offers superior load-bearing capacity relative to its mass, enabling robust support for seats, panels, lighting, electronics, and ancillary equipment while directly contributing to vehicle lightweighting goals.

-

Vibration Damping & Durability: Inherently excellent at absorbing operational vibrations and shock, our brackets reduce stress on both the mounted component and the vehicle structure, minimizing fatigue and extending service life.

-

Design Integration & Complexity: The die-casting process allows for intricate, net-shape geometries that consolidate multiple functions into a single, robust part. Integrate mounting points, cable guides, and reinforcement ribs seamlessly to streamline assembly.

-

Corrosion Resistance & Performance: Utilizing high-performance magnesium alloys and appropriate coatings, our brackets are engineered to meet the environmental and durability specifications of the rail industry.

Ideal for Mounting & Securing

-

Interior Systems: Seat frames, partition supports, luggage rack anchors, and panel mounting brackets.

-

Equipment & Electronics: Housings for control units, sensor mounts, display armatures, and communication device supports.

-

Door & Access Mechanisms: Structural components for sliding door systems and hatch fittings.

-

Auxiliary Components: Brackets for lighting fixtures, signage, handrails, and customer information units.

Manufactured for Compliance & Sustainability

Moldie’s brackets are produced to meet relevant industry standards for mechanical performance and safety. The efficiency of the die-casting process minimizes waste, and magnesium’s full recyclability supports environmentally conscious manufacturing.

Partner with Moldie

Move beyond simple fabrication. Our engineering team collaborates with you to design and produce optimized bracket solutions that reduce assembly time, lower total weight, and provide a reliable foundation for your rail vehicle’s interior and equipment systems.

Choose Moldie’s Magnesium Die Cast Brackets—the strong, smart, and lightweight foundation for secure rail system integration!

Basic information

| Brand | Moldie |

| Mold Base | LKM C50 + P20 for AB, Cast iron etc. |

| Inserts(cavity and core) | Dievar, H13, 8407, 1.2344 or the material you required |

| Standard | HASCO, DME, MISUMI, PUNCH and so on |

| Product Material | ADC12, ADC14, A360, A380, AlSi9Cu3 and so on |

| Mold Treatment | Heat Treatment >HRC45 |

| Product Surface | Sand blasting, Powder coated, Painting, Anodizing, etc |

| Shape & Color | Can be design according to your needs |

| Process | High Pressure Die Casting |

| Certificated | ISO 9001:2015 Certificated |