Die Casting Surface Treatment

At Moldiecasting, we specialize in enhancing the quality and durability of metal surfaces through a wide range of surface treatment services.

These processes modify the outer layer of metals, offering both functional and aesthetic benefits. Our treatments include coating, plating, anodizing, and laser processing, each tailored to meet specific needs.

Electroplating

Electroplating is the process of applying a thin layer of metal over a metal surface, improving both its appearance and durability. The key electroplating services we provide are:

1. Nickel Plating: Often used for smooth, shiny finishes, this treatment is popular for bathroom fixtures and automotive components due to its resistance to wear and corrosion.

2. Chrome Plating: Known for its mirror-like finish, chrome plating is widely used in automotive trim and accessories, available in both bright and matte finishes to suit different styles.

3. Galvanization: A protective layer of zinc is applied to steel or iron, effectively preventing rust and corrosion. Ideal for outdoor and structural applications.

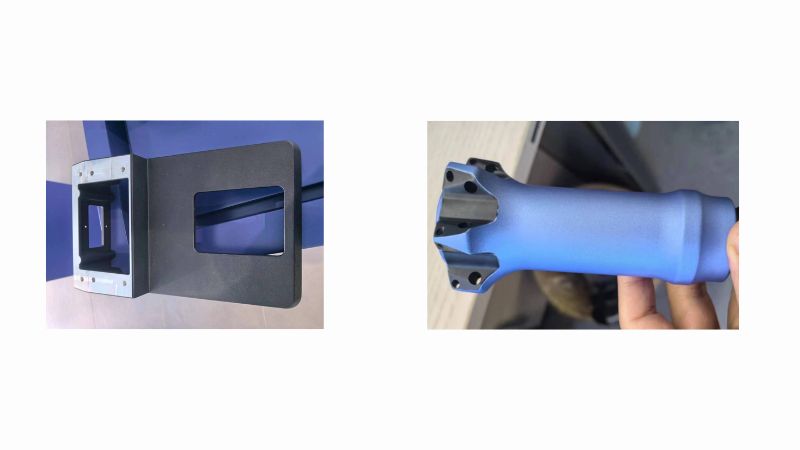

Coating

Coating metal surfaces provides a protective shield while enhancing the metal’s appearance. The coating services we offer include:

1. Powder Coating: Available in a variety of colors and textures, this durable coating is baked on to create a hard, long-lasting finish.

Printing

Anodizing

Anodizing is an electrochemical process that creates a protective oxide layer on metals like aluminum, titanium, and magnesium. This layer boosts corrosion resistance and can also add vibrant colors that resist fading over time. With thickness options ranging from 0.5 µm to 150 µm, anodizing offers tailored protection for different applications

Laser Processing

Laser treatment is used to enhance the surface properties of metal. This includes:

1.Laser Hardening: The laser hardens the surface layer of metal, improving its wear resistance and longevity.

Polishing

Polishing is essential for achieving a smooth, shiny surface on metal. It enhances both the appearance and durability of the material, and can be tailored to the hardness of the metal.

Shot Blasting

Shot blasting involves propelling tiny particles at high speed onto a metal surface to clean it and remove debris such as rust or old coatings. This prepares the surface for further treatments, improving both appearance and functionality.

Sticker Application

Moldiecasting provides Water Applique Stickers, a unique surface treatment that applies pre-printed designs to metal using water and pressure. This technology offers complete customization, allowing intricate patterns and logos to be applied to metal surfaces. The design is highly resistant to scratches, chemicals, and abrasion, ensuring long-lasting durability.

With our expertise in metal surface treatments, Moldiecasting delivers tailored solutions that enhance both the functional and visual appeal of your products. Whether for industrial, automotive, or decorative purposes, our surface treatments ensure superior quality and lasting performance.