Semi-solid die casting blends ideas from die casting and forging to shape half-liquid, half-solid metal with precise control. This approach fits well where strength, accuracy, and clean surfaces matter.

In this article, we will break down the technical jargon and concepts to help you better understand how semi-solid metal works, what the different die casting processes are, and where semi-solid casting delivers clear benefits.

Semi-Solid Die Casting Basics: What Is It Exactly?

Semi-solid die casting (SSM) forms metal parts from a semi-solid state, not a fully liquid melt. The metal enters the mold as a thick slurry made of solid particles suspended in liquid metal.

During this process, the advanced control system ensure that the metal stays between its solidus and liquidus temperatures, often with a solid fraction of about 30% to 65%.

Understanding the “Slurry” State

The key to this process is the heated semi-solid slurry. It contains rounded solid grains surrounded by liquid metal, rather than sharp dendrites (tree-like, branched crystal structures that form as molten metal solidifies).

The slurry shows thixotropy, which is a property where a liquid or semi-solid material becomes less viscous (thinner) and flows easily under stress, and thickens into a gel-like structure that holds shape once the stress is removed.

These two properties correspond to their respective parameters for controlling slurry quality:

- Temperature control for precise slurry solid fraction (the proportion of solid metal within a liquid-solid mixture)

- Shear rate for thixotropy control that shapes the grains and controls viscosity

Metals & Alloys Used in Semi Solid Die Casting

Manufacturers use semi-solid die casting mainly with non-ferrous alloys. Aluminum, magnesium, and certain copper alloys work best due to their melting ranges and flow behavior.

Common material choices include:

| Material | Key Benefits |

|---|---|

| Aluminum alloys | Good strength, heat treatable, widely available |

| Magnesium alloys | Low weight, excellent flow, fast cycle times |

| Copper alloys | High strength, limited use due to temperature range |

These alloys respond well to solid–liquid coexistence. They form stable slurries and maintain predictable behavior during injection. High-melting alloys see limited use due to tooling and temperature constraints.

Different Semi-solid Metal Casting Processes

Each semi-solid die casting manufacturing process manages slurry generation, heating, and injection in a different way to balance strength, accuracy, and cost.

Thixocasting Method

Thixocasting relies on a pre-cast billet (a specially treated solid metal rod) with a fine, non-dendritic structure. The billet heats through induction heating (using an electromagnetic field to cleanly and efficiently heat conductive materials) until it reaches a semi-solid state.

Then, the thixocasting process injects this slurry into a closed die using high pressure. The lower temperature reduces gas pickup and shrinkage, and the finished parts show tight tolerances and smooth surfaces.

The method offers strong control but adds cost due to billet preparation and handling.

Key features

- Controlled billet quality

- Precise temperature window

- High repeatability for complex parts

Rheocasting Method

Rheocasting forms the slurry directly from molten metal instead of a rod. The process cools the melt while using mechanical stirring or other mixing methods. This action breaks up solidifying grains into rounded particles.

The process also feeds the slurry into the cavity of a die, often with standard high-pressure die casting equipment. It removes the need for pre-cast billets and reduces material steps.

Rheocasting works well for high-volume parts. It offers flexibility in alloy choice and lower material cost.

Common advantages

- Direct slurry generation

- Lower raw material cost

- Good fit for large-scale production

Thixomolding for Magnesium Alloys

Thixomolding adapts semi-solid processing for materials including magnesium alloys. It feeds solid magnesium chips into a heated barrel under a protective gas.

Same as the others, the chips melt into a slurry, which is then injected into a closed mold by a screw, similar to plastic molding. The process runs at lower temperatures than conventional die casting, which improves safety and control.

Manufacturers choose thixomolding for thin-walled and lightweight parts that support strong dimensional control and clean surfaces. The method sees wide use in electronics and automotive housings.

Typical traits

- Chip-based feedstock

- Enclosed, clean operation

- Best fit for magnesium alloys

Emerging Methods: SIMA & More

SIMA stands for “Strain-Induced Melt Activation.” It first deforms the alloy through rolling or forging. Controlled heating then creates a fine semi-solid structure during partial melting.

This approach supports small or complex parts that need uniform grains. SIMA is often paired with thixocasting or other semi-solid forming steps.

Other emerging methods focus on better slurry control and faster cycle times. They aim to expand semi-solid forming to new alloys and part sizes while keeping costs stable.

Key Advantages of Semi Solid Die Casting

Enhanced Mechanical Performance

Semi solid die casting improves key mechanical properties by reducing porosity and shrinkage. The process limits trapped gas and voids, so the parts it produces often reach higher density than traditional die casted parts.

What’s more, a fine, uniform microstructure forms during solidification. This structure supports higher strength and more stable performance under load. Many aluminum and magnesium parts show better fatigue resistance as a result.

The process also supports improved ductility. Parts can handle heat treatment and welding with less risk of cracking. This is important for structural parts that face repeated stress or impact.

High Dimensional Accuracy and Surface Finish

Semi solid die casting delivers strong control over shape and size. The thick metal flow fills the mold smoothly and avoids turbulence, which helps achieve tight tolerances across the entire part.

The process produces a clean and even surface finish. Many parts leave the mold with smooth surfaces that need little or no polishing, coatings, or cosmetic machining.

Additionally, dimensional stability stays consistent from part to part. Manufacturers rely on this repeatability for assemblies that demand precise alignment. Less variation also reduces inspection time and scrap.

Complex Geometries and Tight Tolerances

The semi solid slurry flows in a controlled way, which supports complex geometries. Thin walls, ribs, and internal channels form with fewer defects than liquid casting. This expands design options without raising risk.

Parts often qualify as near-net shape (a cast part that is very close to its final dimensions) components, which limits extra cutting or shaping and reduces reliance on machining.

Designers also benefit from stable tight tolerances. The process holds shape during cooling, even in thick-to-thin transitions. This stability helps when parts must fit with seals, bearings, or electronic components.

Lower Production Costs and Energy Usage

Semi solid die casting runs at lower temperatures than fully molten processes of traditional die casting. This reduces energy use per cycle and lowers thermal stress on tooling. Longer mold life helps control production cost over time.

Reduced porosity and shrinkage lead to fewer rejected parts. Scrap rates often drop, which improves production efficiency and shortens lead times. Higher yield also means more finished parts from the same amount of metal. These savings add up in large production runs.

Applications of Semi Solid Die Casting

Automotive and Transportation Components

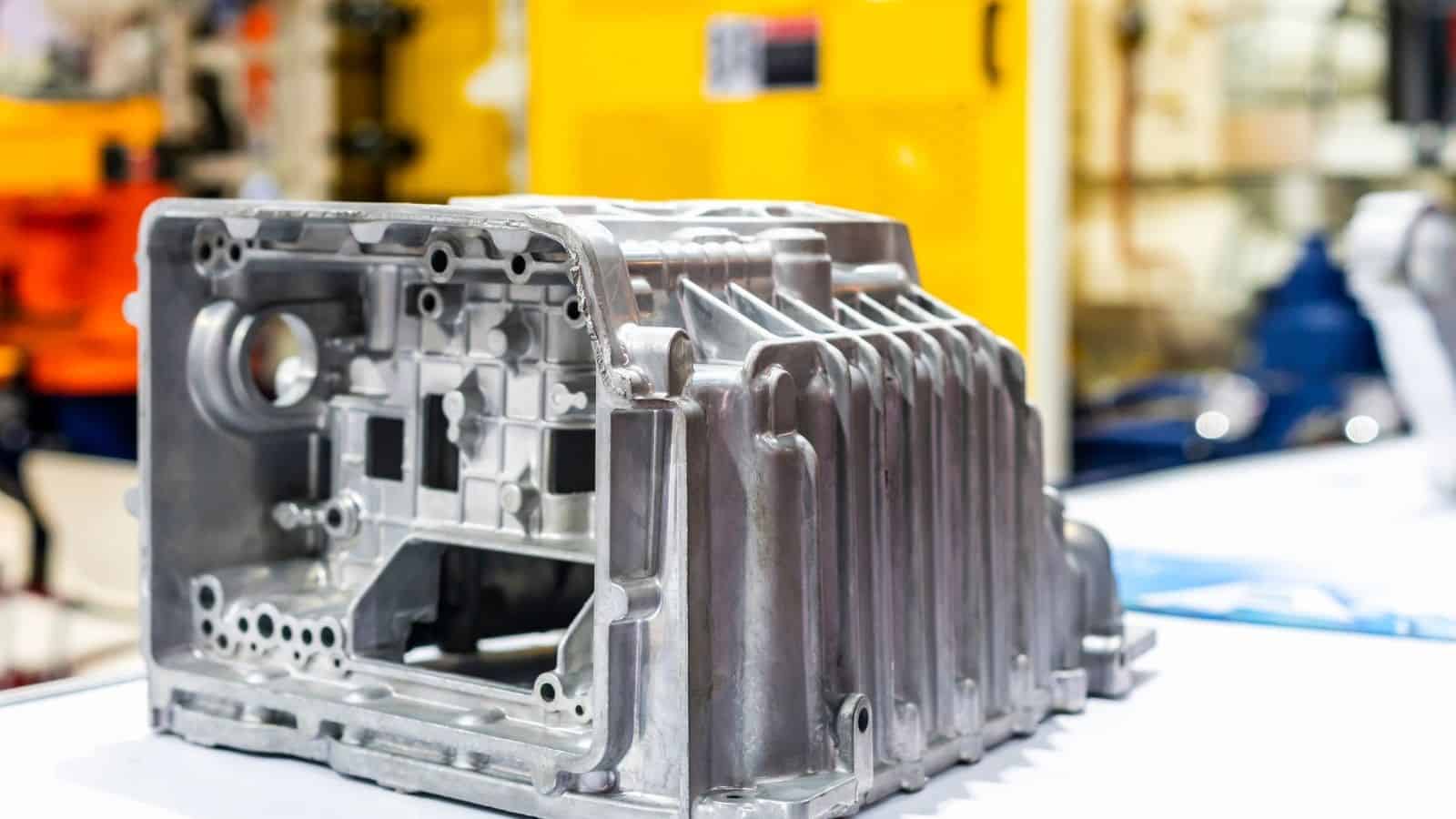

Automakers use semi solid die casting to make automotive components that carry high loads and face constant stress. Common parts include steering knuckles, engine mounts, suspension arms, and structural brackets.

Some manufacturers also apply the process to engine blocks and transmission cases. The lower casting temperature reduces shrinkage and distortion. This control helps meet strict size limits and lowers machining time.

Electric vehicles also rely on this process. It supports lightweight aluminum and magnesium parts that improve range without losing strength.

Aerospace and Defense Applications

Aerospace programs use semi solid die casting for aerospace components that must meet tight safety and weight limits. Typical aerospace parts include housings, brackets, and landing gear components made from aluminum or magnesium alloys.

Defense suppliers use the process for parts that need repeatable quality at scale. It supports consistent output while meeting material standards.

Consumer Electronics and 5G Housings

Electronics makers use semi solid die casting to produce thin, rigid frames with clean surfaces. Examples include computer frames, tablet housings, and 5G antenna housings. These parts need tight tolerances to protect sensitive hardware.

The process allows complex internal features such as ribs and heat paths. This design freedom supports thermal control and structural stiffness in compact devices.

Low porosity also improves shielding performance. That matters for 5G systems, where stable signal performance depends on precise metal geometry.

Emerging and Industrial Uses

Industrial equipment makers apply semi solid die casting to pumps, power tools, and robotic parts. These components often need strength, wear resistance, and repeatable size across large batches.

The process also supports copper-based alloys for thermal and electrical parts. Manufacturers use it for heat sinks, motor housings, and connectors where solid metal flow improves performance.

New uses continue to appear in energy, automation, and mobility systems. As tooling and alloy options expand, more industries adopt the process for high-volume, high-quality metal parts.

Conclusion

Semi-solid die casting bridges liquid casting and solid forging, offering strength, precision, and efficiency. Methods like thixocasting and rheocasting enable tailored production. With benefits like reduced porosity and energy use, it’s ideal for lightweight, precise metal parts, driving wider adoption in demanding industries.

Frequently Asked Questions (FAQ)

Is semi-solid die casting more expensive than traditional die casting?

While the initial setup and tooling can be more costly, semi-solid casting often leads to lower total cost per part in high-volume production. Savings come from reduced energy use (lower temperatures), less material waste (near-net shape), lower scrap rates, and decreased secondary machining. For complex, high-performance parts, the improved yield and quality frequently justify the investment.

How does the mechanical strength compare to standard die casting parts?

SSM parts are significantly stronger and more reliable. The reduced porosity and fine, uniform microstructure lead to higher tensile strength, improved fatigue resistance, and better ductility. This allows them to be used in structural applications where traditional die castings might fail.

Can semi-solid die casting replace forging?

Although it does not completely replace forging, SSM can produce parts that approach or match the mechanical properties (density, strength) of forgings, especially for complex shapes that are difficult or expensive to forge. It is often seen as a complementary or competitive process to forging, particularly when excellent surface finish and tight tolerances are needed directly from the mold.

What are the main limitations of semi-solid die casting?

The primary limitations are material scope and upfront complexity. It is most effective with specific aluminum, magnesium, and some copper alloys. High-melting-point alloys like steel are not suitable. The process also requires precise temperature and slurry control, necessitating specialized equipment and expertise, which can be a barrier for smaller operations, prototyping, or low-volume runs.