Porosity resulting from trapped gas or solidification shrinkage undermines the integrity of die-casting parts. However, with modern porosity detection and diagnostic tools, manufacturers transform these porosity defects into actionable data and use them to quantify risks, find cost-effective remedial measures, and ultimately ensure the efficiency and quality of your casting parts.

Porosity Detection Methods in Die Casting

Accurate porosity detection ensures durability, sealing, and dimensional integrity in die-cast components. Engineers rely on several non-destructive testing (NDT) methods to locate and evaluate internal and surface voids without damaging parts. The most suitable method depends on the casting material, wall thickness, defect location, and quality level required.

X-ray Inspection and Radiographic Testing (RT)

X-ray inspection and radiographic testing (RT) detect internal voids by passing X-rays or gamma rays through the casting. Denser metal areas absorb more radiation than air-filled pores, producing grayscale contrast on a film or digital detector.

Engineers can view the distribution, size, and shape of porosity directly from the image. This visual clarity makes RT valuable for aluminum and zinc die castings, because the internal gas porosity greatly affects their tightness and strength.

Advantages:

- Detects internal and hidden defects precisely.

- Creates a permanent image record for traceability.

- Works well for complex-shaped or thick-walled components.

Ultrasonic Testing (UT) and Eddy Current Testing (ET)

Ultrasonic testing (UT) introduces high-frequency ultrasonic waves into the casting. When the wave meets a pore or density change, part of the energy reflects back. By measuring reflection time and amplitude, technicians locate and size internal defects. UT is effective for thicker sections and provides rapid, quantitative readings.

Eddy current testing (ET) relies on electromagnetic induction. A coil carrying alternating current generates eddy currents in the casting’s surface layer. Porosity or cracks disturb these currents, producing measurable signal changes. ET is fast and useful for conductive non-ferrous materials such as aluminum and copper alloys.

| Method | Best for | Strengths | Main Limits |

|---|---|---|---|

| UT | Internal or near-surface pores | Deep penetration, good sensitivity | Needs skilled engineers, surface must be smooth |

| ET | Near-surface defects | Quick, contactless, safe | Limited to conductive materials, shallow depth |

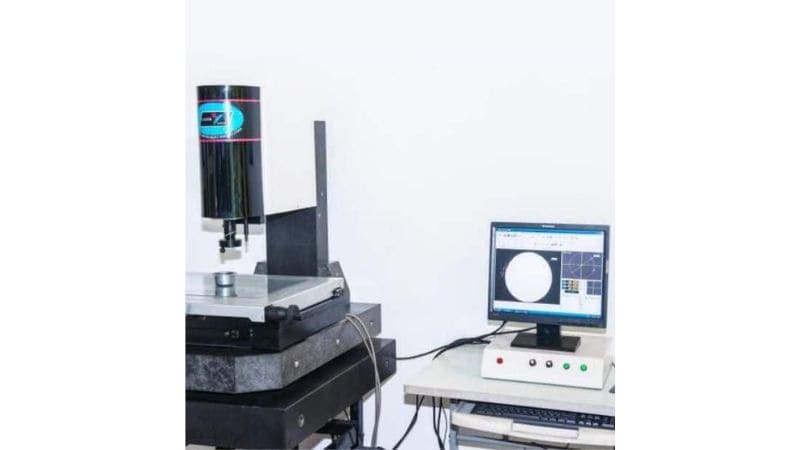

Computed Tomography (CT Scanning)

Computed tomography (CT) or industrial CT scanning provides a three-dimensional image of internal volume. Multiple X-ray projections are digitally reconstructed to reveal the exact size, distribution, and position of pores.

CT delivers higher accuracy than 2D RT, making it ideal for precision and high-value components like automotive housings or aerospace castings. It also allows precise measurement of pore volume percentage and spatial mapping for porosity inspection studies.

However, scanning large parts can take significant time. Engineers often reserve it for prototype analysis, process validation, or root-cause investigations when other NDT methods can not suffice.

Visual Inspection and Surface Porosity Checks

Visual inspection remains the simplest and most immediate porosity testing method. Technicians examine the casting’s surface under proper lighting, sometimes with magnifiers or optical cameras, to detect open pores, blisters, or pits.

For small pores, liquid penetrant testing (PT) or dye contrast may aid visibility by drawing out flaws to the surface. This approach is quick, inexpensive, and suitable for large production runs where deep internal analysis is unnecessary.

Surface tests work well for identifying leak paths, machining defects, or coating adhesion problems. Still, they cannot locate enclosed voids, so manufacturers often combine them with other testing methods for comprehensive porosity detection coverage.

Evaluation and Classification of Porosity

Accurate evaluation of porosity helps determine whether an aluminum alloy casting meets structural, sealing, and functional requirements. Measurements of pore size, distribution, and frequency directly affect mechanical strength and airtightness, while data-based simulations and standards ensure consistency across production batches.

Porosity Grading Standards

Porosity grading sets measurable limits for acceptable defects in die castings. Standards such as ISO and ASTM classify aluminum alloy castings by pore size, density, and location. These levels guide acceptance criteria for both visual and nondestructive testing.

Quantitative Analysis: Pore Size and Distribution

Quantitative evaluate casting performance by analyzing pore size and spatial distribution. Fine micropores below 0.1 mm may not weaken the structure but can reduce sealing effectiveness in hydraulic or engine components.

Technicians often calculate porosity percentage as the ratio of pore area to total cross-sectional area. Even small clusters of pores near critical stress zones can lower fatigue resistance. For aluminum die castings, uniform dispersion of fine pores is preferred to isolated large voids.

Spatial mapping or 3D reconstruction identifies whether defects concentrate near gates, thick walls, or cooling junctions. These results help engineers adjust injection pressure, venting, and cooling rates to reduce local gas entrapment.

Statistical Analysis and Simulation Approaches

Statistical analysis and simulation tools help predict porosity trends before final production. Engineers use regression and correlation studies to link process parameters such as melt temperature, shot speed, and vacuum level to the probability of porosity.

Computer-based casting simulation models, especially in aluminum alloys, estimate defect risks by visualizing air entrapment and solidification shrinkage. Validated models are compared with CT or ultrasonic test results to refine accuracy.

Data from repeated production runs feed into control charts or process capability indices (Cpk). When statistical data show rising pore counts, parameters are adjusted accordingly. This feedback loop ensures consistent quality, helping manufacturers maintain compliance with internal and external quality standards.

Porosity Remediation and Post-Treatment

Correcting porosity in die-cast parts often involves sealing microscopic voids, improving surface density, and verifying material integrity under controlled pressure conditions. These treatments enhance part performance, reduce leakage, and strengthen components subjected to mechanical or thermal stress.

Vacuum Impregnation and Pressure Sealing

Vacuum impregnation seals micro-porosity that penetrates a part’s cross-section. The process uses a vacuum chamber to remove trapped air from the pores, then draws in a low-viscosity sealant—typically a polymer resin. After curing, the sealed pores create a continuous barrier that prevents fluid or gas leakage.

This technique is especially useful for aluminum and magnesium die castings used in engines or hydraulic components. A key advantage is that it preserves the casting’s dimensional accuracy while improving pressure tightness. Many manufacturers follow up with pressure testing to confirm the seal integrity.

| Step | Action | Purpose |

|---|---|---|

| 1 | Vacuum cycle | Removes air from internal pores |

| 2 | Impregnation | Introduces sealing resin |

| 3 | Curing | Hardens resin for permanent sealing |

| 4 | Pressure testing | Verifies leak-free performance |

Effective impregnation improves the component’s reliability, especially in applications requiring long-term fluid containment.

Surface Finishing and Anodizing

Surface finishing enhances appearance and functional performance while minimizing the risk of corrosion. Anodizing—common for aluminum die castings—forms a controlled oxide layer that increases hardness and wear resistance.

Before anodizing, the surface must be cleaned and smoothed to remove contaminants and close shallow pores. Techniques such as mechanical polishing or abrasive blasting can improve coating adhesion.

If porosity remains after casting, the anodizing process can accentuate defects rather than conceal them. To avoid this, impregnation often precedes anodizing to ensure surface sealing. The resulting part demonstrates improved corrosion resistance, aesthetic uniformity, and extended service life.

Common surface finishing methods include:

- Anodizing: Oxide coating for corrosion resistance

- Electropolishing: Removes high points for smoother finishes

- Powder coating: Adds protective and decorative layers

Hot Isostatic Pressing (HIP) and Quality Control

Hot Isostatic Pressing (HIP) removes internal porosity by applying high gas pressure and temperature uniformly around the casting. Under these conditions, metal atoms diffuse across pore walls, closing internal voids without melting the part. This process increases density and mechanical strength, making it ideal for critical aerospace or automotive components.

HIP operates inside a pressure vessel using an inert gas at elevated temperatures (below the alloy’s melting point) and isostatic pressures. It is often combined with nondestructive testing afterward to confirm pore elimination and detect any structural flaws.

Achieving Robust Porosity Control in Your Production

Excellent porosity control is a competitive advantage that any quality manufacturer should have. That is why we at Moldie manage to enhance product quality and accuracy through advanced equipment and experienced teams in die-casting industry. Contact us today for your lighter, stronger, and flaw-tolerant parts!

Frequently Asked Questions (FAQ)

How does porosity affect the recyclability or cost-efficiency of die-cast components?

Porosity itself doesn’t hinder the recyclability of the metal scrap. However, significant porosity leads to part rejection and scrap, which increases the overall energy consumption and costs per usable part. Effective porosity detection and prevention are therefore key to improving material efficiency and supporting economical manufacturing goals.

Does vacuum impregnation affect the weight or machinability of a part?

The weight increase from impregnation resins is typically negligible. Regarding machinability, properly cured sealant within pores generally does not hinder machining. In fact, it can prevent cutting fluids from being trapped in voids and improve tool life by creating a more uniform material structure.

Which porosity detection method is the fastest for production lines?

For high-speed surface defect screening on conductive materials (like aluminum), Eddy Current Testing (ET) is often the fastest. For volumetric inspection, automated X-ray systems can provide rapid feedback. The choice depends on whether surface or internal defects are the primary concern.

Can porosity be completely eliminated in die casting?

It is challenging to eliminate porosity entirely in standard die casting. The goal of process optimization is to minimize and control it to acceptable levels defined by the part’s function. Techniques like vacuum-assisted die casting and HIP post-treatment are used to achieve near-zero porosity for the most demanding applications.