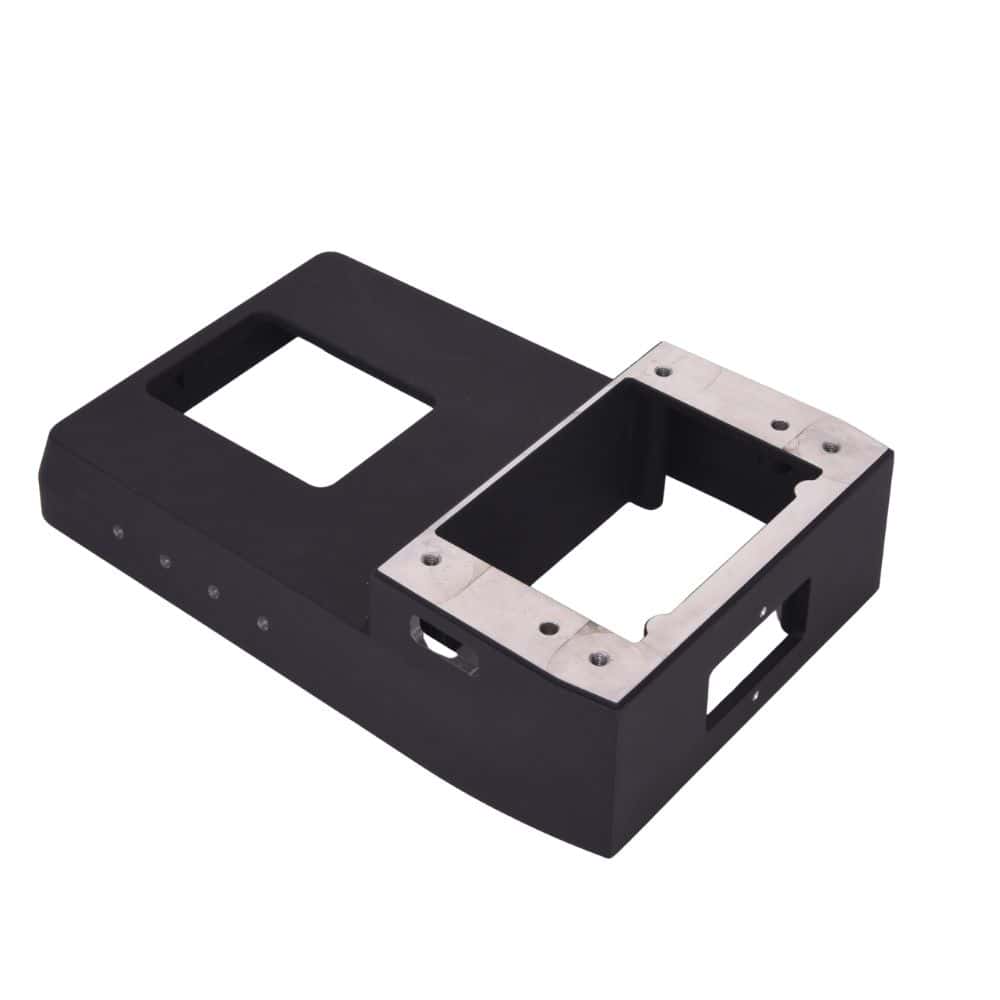

High-Quality Die Cast Aluminum Enclosure

As a specialist in die cast aluminum enclosure production, we construct our mold bases from robust materials including LKM C50, P20, and cast iron, ensuring lasting structural integrity and performance.

Each die cast aluminum enclosure is manufactured from high-quality alloys such as ADC12 and AlSi9Cu3 (A380), complying with leading international standards including HASCO, DME, and MISUMI.

Precision-crafted inserts made from premium steels like Dievar and H13 are tailored to meet custom requirements, supporting complex geometries and strict tolerances.

Every die cast aluminum enclosure undergoes advanced heat treatment, achieving surface hardness above HRC45 for improved durability and resistance to wear.

We offer a wide range of aesthetic finishes—such as sandblasting, powder coating, and anodizing—all customizable in shape and color to align with your design vision. The high-pressure die casting process guarantees dimensional accuracy and consistent quality.

Our production system is ISO 9001:2015 certified, providing assurance of reliability and excellence in every product.

Choose us as your trusted die casting parts supplier—contact us today to discuss your project or place an order.

Trade information

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port |